Reading/Writing/Flashing the Rover MEMS3 ECU

Download

Link: https://andrewrevill.co.uk/Downloads/MEMS3Tools.zip

A while back a wrote an article on cloning the

Rover MEMS3 ECU https://andrewrevill.co.uk/MEMS3Cloning.htm.

This process was fairly involved and invasive. It involved dismantling the ECU,

removing the memory chips and reprogramming.

Since then Iíve been working on cracking the process of flashing full maps

and firmware to the MEMS3 ECU without any disassembly. I wanted to be able to

copy the full firmware and maps from one ECU to another in a simple way through

the OBDII port only, similar to the way that well-known mapping specialists do.

This goes well beyond the map reading and writing capabilities of tools like

Galletto as it allows the full operating firmware of the ECU to be cloned.

Itís taken me about a year of chipping away at it Ö but Iíve finally got

something robust and useable. Iíve written a little MEMS3 Flasher application

that allows ECUs to be read and written very simply.

This allows you to clone the complete firmware and map from any MEMS3 ECU

to any other with the same part number or compatible hardware. So for example

you can make a backup copy of Supersport ECU by cloning it onto a standard

Rover ECU cheap off eBay.

This works with standard tunes and modified remaps too.

Hardware Required

One objective I set myself was that no expensive hardware should be

required. In order to use my flasher, the only thing you need (other than a

Windows laptop with a USB port to run it on) is a VAG-COM diagnostic cable such

is this: https://www.ebay.co.uk/itm/USB-Cable-VAG-COM-KKL-409-1-Auto-Scanner-Scan-For-Car-Seat-Diagnostic-Tools-BT/223941245849?hash=item3423f03b99:g:ddcAAOSwnT5eYeD5.

Any similar OBDII cable described as a VAG COM KKL 409.1 cable or similar

should work fine. These are widely available very cheaply on eBay. Depending on

the drivers that come with the cable it will either install into your system as

an FTDI Direct device, a Windows COM serial port or both. Avoid cables that

claim to have an ELM327 chip as these are a completely different interface, and

Galletto flasher cables as these seem to have the FTDI chips programmed

differently.

The MEMS3 Flasher Tool

This is a simple Windows EXE, no installation required. All you need to do

is plug the cable into the laptop and the car and run the program and itís

ready to go. You can download a ZIP of the EXE file here: https://andrewrevill.co.uk/Downloads/MEMS3Flasher.zip.

What Does It Do?

Iíve kept it simple from a user perspective. The temptation was to fill it

with fancy features but I decided that simplicity was in order. As the user

sees it, it has a simple job to do; read and write ECUs and allow the data to

be saved and loaded to and from files. It needs to do that one job really well.

It works like a classic EPROM programmer. You click ďReadĒ to read the data

from an ECU into a memory buffer, ďWriteĒ to write the current memory buffer

out to an ECU. You click ďSaveĒ to save the current memory buffer to a file and

ďLoadĒ to load previously saved data. Thatís about it really!

It specifically supports the MEMS3 family of ECUs only, so thereís no

selection or configuration required. Just plug and play.

Some other programming tools like Galletto 1260 do allow you to do

something similar with the map data. Iíll go into it in more detail below but

this is of limited use as each map is built to work with a particular version

of the ECU firmware, of which there are many. This tool allows the full

firmware and map to be transferred between ECUs, meaning you donít have to

worry about compatibility. And Galletto doesnít cross-check the firmware

version compatibility (mine does) so lets you flash incompatible maps (mine

doesnít) Ö and it often doesnít seem to be able to recover the ECU if you do,

leaving it ďbrickedĒ.

Instructions

Basic instructions for using the software are as follows:

INSTALLING THE FTDI CABLE

1.††††††††††† Follow any instructions

that come with the cable to install the appropriate drivers on your system.

READING FROM AN ECU

1.††††††††††† Connect to the ECU. WARNING:

Do not turn on the ignition yet! Plug the FTDI cable into the OBDII port on the

car and into a USB port on the laptop. The ECU seems to check whether thereís

anything connected when it powers on and if not, after that it refuses to talk.

So itís important to get everything connected first. If not, you will need to

either turn the ignition off for something like 10 minutes to allow the ECU to

fully power down, briefly disconnect the smaller of the two ECU plugs to

interrupt the power and force a reset, or briefly pull the 30A ECU fuse from the

fuse box.

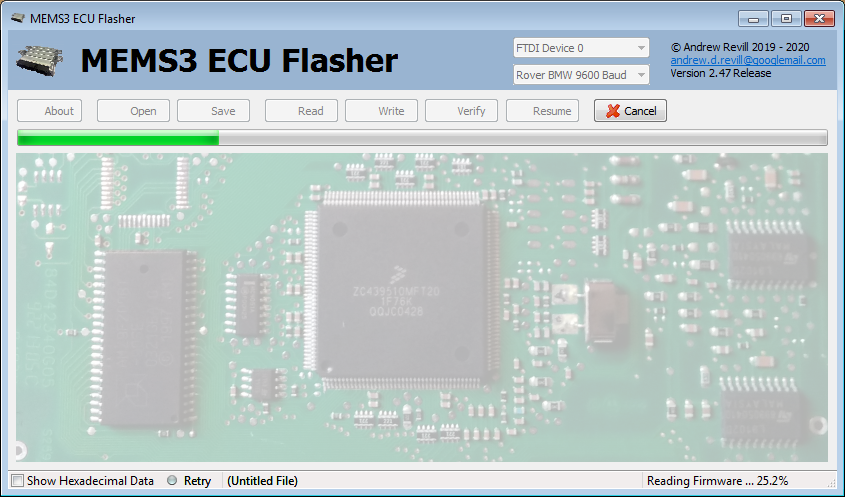

2.††††††††††† Run the MEMS3 Flasher

Application.

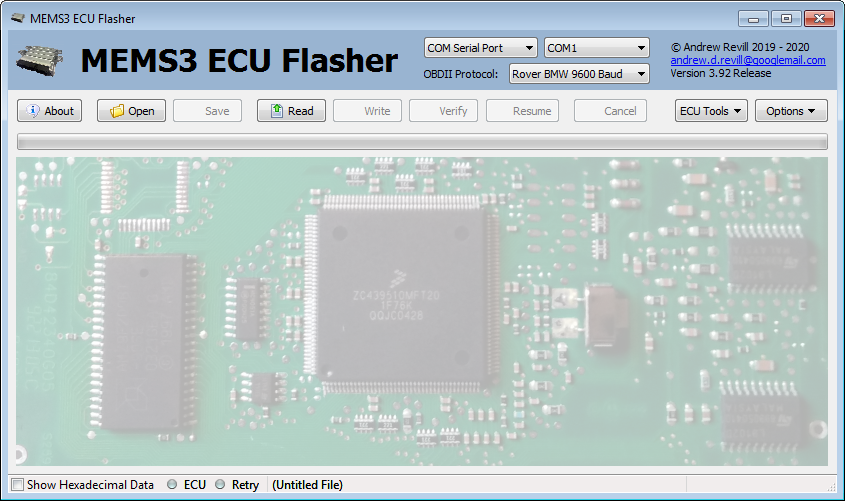

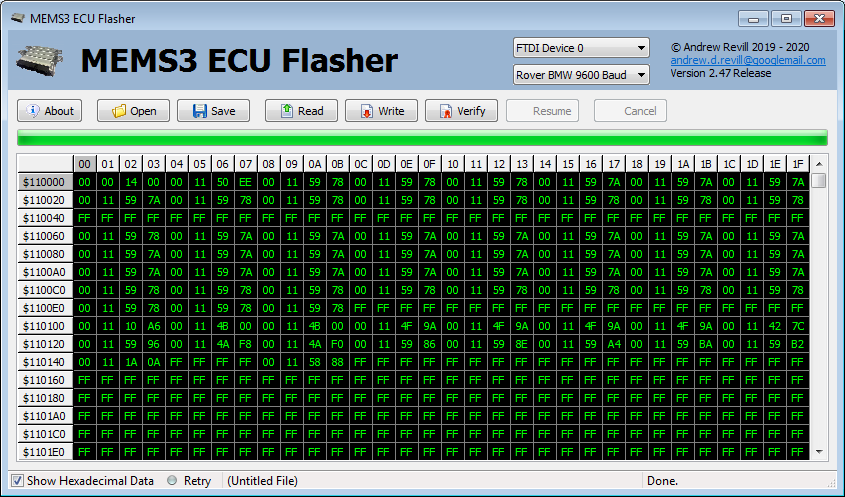

You should see a window like this:

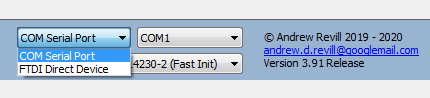

3.††††††††††† Select the OBDII

Connection.

Select the OBDII cable using the combo boxes at the top of the window. It

should show up as either an FTDI Direct Device or COM Serial Port (or both, in

which case it should work fine whichever option you select). You can also

select the OBDII protocol at this stage it required.

†

4.††††††††††† Turn On the Ignition.

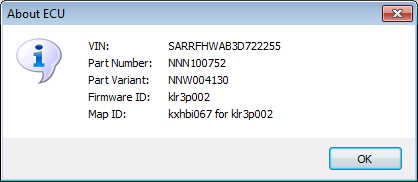

5.††††††††††† Check Your

Connection. Click the About button. The

application will connect to the ECU and display the VIN, Part Number, Part Variant,

Firmware ID and Map ID as shown below. If it doesnít work first time, try

turning the ignition off and on again and then repeating. The ECU can be a bit

temperamental sometimes!

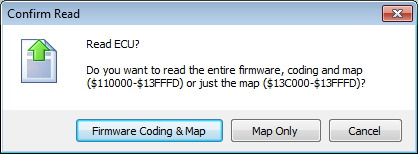

6.††††††††††† Read the ECU. Click

the Read button. You should be presented with a dialog like the one shown

below:

You can choose to read the full firmware (contains the operating software of

the ECU), coding (contains the VIN and Part Variant) and the map (contains the

various tables with the configuration parameters for the engine) or just the

map. If you only read the map, you will be able to write this back to any ECU

with the same firmware version only. If you read the firmware and map, you will

be able to write this back to any compatible ECU. Due to the fairly low serial

data speeds used by the protocols supported by the ECU, reading the map alone

takes about 22 seconds and performing a full read of the ECU takes about 4

minutes 19 seconds.

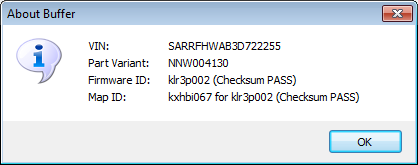

Once the read is complete the system displays a dialog confirming the VIN,

Part Variant, Firmware ID (if these were read) and Map ID for the data in the

internal buffer. These should match the data originally displayed for the ECU.

The messages are all protected by checksums and the protocols I have

implemented include several layers of error checking and recovery so the data should

match in every case. If the transfer is interrupted, you should see that the

Resume button becomes enabled. This will allow you to resume and complete the

read, even if the ECU has been shut down in the meantime.

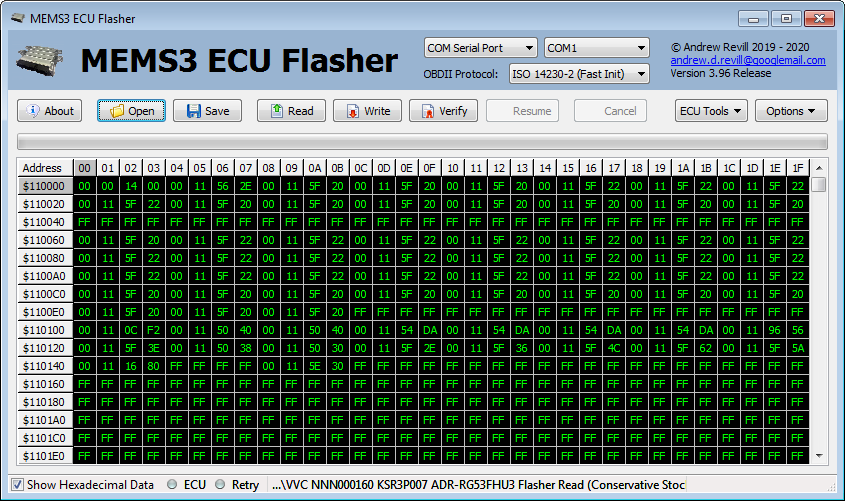

After reading the ECU, the internal buffer data is displayed in hexadecimal

form as show below.

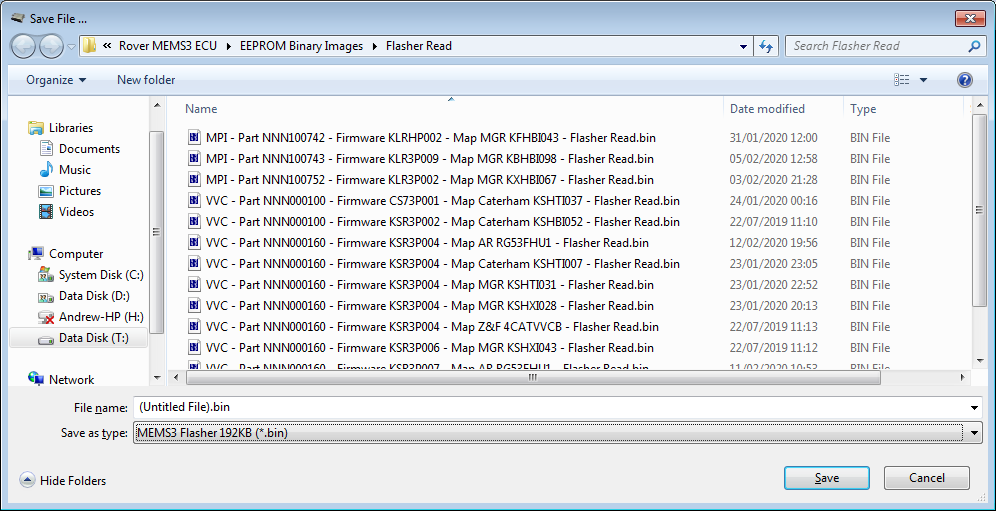

7.††††††††††† Save the Data to a

File. You don't have to save it to a file before writing it back to another

ECU but it makes sense to save a copy. Click the Save button. You will be

prompted for a file name to save the data as a .BIN file (raw binary data).

There are several file formats supported but the default "MEMS3 Flasher

192KB" file format should be fine. The different file formats are

discussed further below.

WRITING TO AN ECU

1.††††††††††† Open a File. If

you are moving straight on to writing to a new ECU, you can skip this step.

However if you return to it at a later data, connect to the ECU, run the MEMS3

Flasher application, turn on the ignition and check your connection exactly as

described in instruction (1) to (4) previously, then click the Open button and

select the file you saved previously.

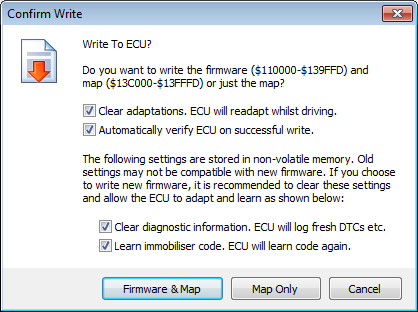

2.††††††††††† Write the ECU. This

is very similar to reading an ECU. Click the Write button. You should be

presented with a dialog like the one shown below. Again you can choose to write

the full firmware and map or just the map alone. If you choose to write just

the map, the application will check the firmware in the ECU to make sure it is

the same version as the one the map is compiled for and will refuse to write an

incompatible map to the ECU.

There are a few extra options when writing:

a)††††††††††† Clear Adaptations. This

will clear any fueling adaptations in the ECU, as they may not be appropriate

with a modified map. The ECU will readapt over a couple of hundred miles of

mixed driving. During this time the emissions and fuel economy may not be as

good as they normally are as the fueling may be slightly incorrect.

b)††††††††††† Automatically verify ECU

on successful write. This will cause the application to perform a read of the

ECU once the data has been written, to confirm that the data now in the ECU

matches that in the buffer. This is a bit of a "belt and braces"

solution as the ECU appears to verify internally that each block is written

correctly as received and the communications use checksums to allow the ECU to

confirm that each message received is as it was sent, so other than for

failures of the software or very unlucky corruptions that leave the checksums

unchanged, the data transfer should be reliable. For peace of mind though, I

normally verify after writing.

c) Clear diagnostic information. This option only applies when writing the

firmware. Because I can't be sure that the format used for storing information

in the working non-volatile memory of the ECU is identical or compatible

between firmware versions, by default the application clears any diagnostic

information. The ECU will then continue to log new diagnostic information for

any current faults.

d) Learn immobiliser code. Again this only applies when writing the

firmware. Again, as I cannot guarantee that the format used for storing the

immobiliser code will always be compatible between firmware versions, by

default the application clears the immobiliser coding and tells the ECU to

re-learn it from the immobiliser. The ECU will then be free-running initially

but the first time it sees the immobiliser disarmed it will learn the code and

again be paired with that immobiliser.

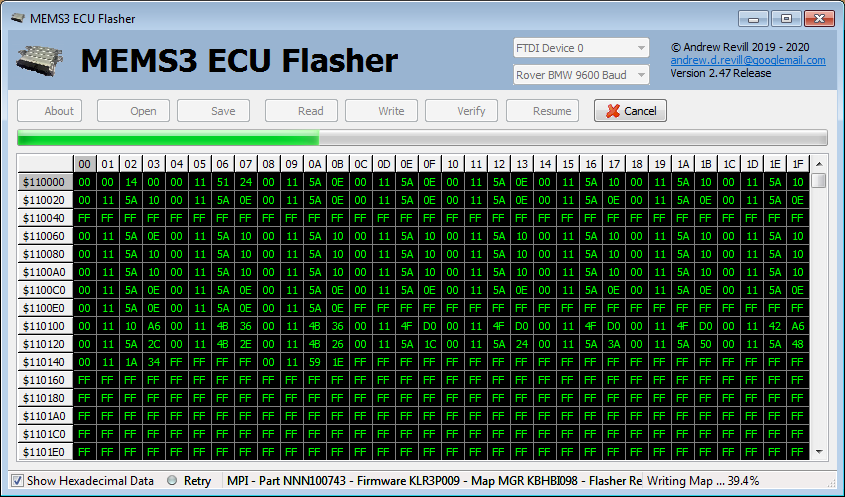

Due to the fairly low serial data speeds used by the protocols supported by

the ECU, writing the map alone takes about 24 seconds to write and 22 second to

verify, so 46 seconds in total. Performing a full write of the ECU takes about

3 minutes 44 seconds to write and 4 minutes 19 seconds to verify, so just over

8 minutes in total. The ECU will reboot at the end of the write, you will hear

the fuel pump priming as though the car ignition was just turned on.

Try not to interrupt the process of writing to the ECU as the ECU will not

run the engine with only a partial firmware or map. As for reading, if the

transfer is interrupted, you should see that the Resume button becomes enabled.

This will allow you to resume and complete the write in most cases. See the

section on Robustness & Risks below.

License & Warranty

Iíve decided to release the executable into the public domain. Feel free to

copy it, share it use, distribute it, give it to your mates, do what you want

with it. You can even sell copies if you can find somebody daft enough to pay

for something that Iím giving out free! I just want it out there as a tool that

people can use if they need it. I think itís pretty robust but itís probably

not perfect, feel free to let me know if you find anything wrong, thereís an

email link in the top right hand corner. Iíll try to fix things that get found

and keep it maintained but Iím not offering any kind of warranty or guaranteed

service level though. This has been and will always be a side project for me.

Source Code

The application is developed in Delphi 10.3, Community Edition. At the

moment Iím not releasing the full source code but if anyone really wants to

know how it works and has a need for parts of the code Iíll happily share.

On Bench or In Car?

The application has been written to allow the ECU to be reflashed in the

car through the OBDII port. You could also use a simple bench testing harness

such as the one I described here: https://andrewrevill.co.uk/KeyProgrammer.htm.

Doing it in the car is the easiest and means that you donít need to buy or

build expensive hardware. It also pretty much guarantees a reliable power supply.

Iíve done most of my development work on the bench then tested on my car.

File Formats

The MEMS3 flasher loads and saves binary files with .BIN extensions. It

supports a number of different types of binary files and it recognises the type

of file from the file size. The following types are supported:

∑

Flasher Files - 196,606 Bytes (192kB - 2 unreadable bytes) - These are the

native file format for the application and contain the full firmware and map.

∑

Firmware Files - 172,032 Bytes (168kB) - These contain only the firmware

with no map.

∑

Map Files - 16,382 Bytes (16kB - 2 unreadable bytes) - These contain only

the map.

∑

EEPROM Files - 262,144 Bytes - These contain the full boot loader, firmware

and map. They are files obtained by reading the EEPROM chip on an EEPROM read

off the board as I did in my original article. Because of the way the

microcontroller addresses 16-bit memory, each pair of bytes in this kind of

file is exchanged.

In normal use, you would probably only need to use the normal Flasher files.

See the section on the Memory Map below for more information about the memory

areas covered by these file formats.

Hardware Compatibility

There is no check on whether the firmware you are flashing is compatible

with the actual ECU youíre flashing it to. The firmwares donít seem to contain

hardware part numbers to cross-check. I guess thatís something that was managed

by Roverís TestBook system originally.

MEMS3 is a modular architecture (thatís what the first ďMĒ stands for).

This means the basic core ECU is common across a wide range of models, but ECUs

with different part numbers either do or donít have a number of additional

hardware and software modules installed. For example, looking the circuit

boards, there are chips that are only present in VVC ECUs and there are other

chips such as a CAN controller which are only present in ECUs for use with

automatic gearboxes.

Each ECU has a part number starting with NNNÖ and a part variant starting

with NNWÖ

I think the NNN code relates to the physical hardware and the NNW to the

firmware installed. From all the testing Iíve done, you should be safe to copy

between ECUs with the same NNN number. In actual fact there is more flexibility

than this; for example the early MGF Trophy 160 ECU NNN000100 and the later MG

TF 160 ECU NNN000160 look to be identical hardware to me, and Iíve had no

problems copying firmware and maps between them. But if you stick using ECUs

with the same NNN part number you should be safe.

Iíve played with what happens if you flash incompatible firmware on an ECU.

I flashed VVC 160 firmware and maps onto a Freelander ECU just to see what

happened. The answer is that it worked surprisingly well! Nothing horrible

happened, the engine VVC engine started and ran fairly normally, it probably wouldnít

have run the engine very well under load as the map would have been wrong and

it wouldnít have controlled the VVC solenoids, it logged a few faults with the

VVC system (which was missing!) but other than that it ran the ignition and

injection happily enough and more to the point, it was still happy to

communicate so I was able to just flash the original Freelander firmware and

map back on and it was all happy again.

Robustness & Risks

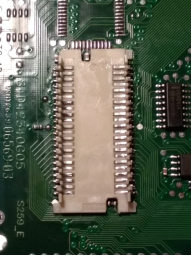

Whilst developing this, I built myself a couple of heavily modified test-mule

ECUs. One of the things I did was to replace the main EEPROM memory chip with a

socket, so I could plug the chip in and out easily. It was a bit fiddly and I

had to carefully trim the sockets to fit around some small surface mount

components close to the chip but it worked well.

††††††††††††††

††††††††††††††

This allowed me to look on the PC what I was actually doing to the memory contents,

but the main idea was that if and when something went wrong and I ďbrickedĒ the

ECU (i.e. got it so messed up that it would no longer communicate well enough

to allow me to put it back again) I could easily reprogram it on the EEPROM

programmer.

In the whole time I have been developing this, during which I must have

flashed eight or nine different ECUs of various types a hundred times or more,

I have to say I only ďbrickedĒ one once, and that was when I was first writing

the code that allowed writing to recover after being cancelled or experiencing

an error; I mistakenly carried on writing the data from where it left off but

started again at the beginning of the EEPROM chip, which obviously just made a

complete mess.

Since releasing the tool Iíve put a lot of work into fail-safety. In my

initial write up I voiced some concerns over possible risks of ďbrickingĒ an

ECU if a write failed. Since then, Iím pretty sure Iíve come up with a

fail-safe write procedure which on paper and in practice should not run the

risk of leaving the ECU in a ďbrickedĒ condition. Although I wouldnít recommend

it, you can now interrupt any process at any point and the ECU will be left in

a condition where it will still boot up safely ready for you to repeat the

operation. I have repeatedly tried to ďbrickĒ an ECU with the latest code by

doing all of the following many times, at many different points in the process,

both during full firmware write and map updates, without any problems:

- Turning off the

ignition.

- Pulling out the

ECU connectors.

- Pulling out the

OBDII connector.

- Pulling the USB

cable out of the back of my laptop.

- Killing the

mapping application through Task Manager.

- Rebooting my

laptop.

With the latest code, none of these have been able to induce any serious

issues at all. In the worst case (in fact in pretty much every case) you just

need to turn the ignition off and on again to reset the ECU, then make sure

everything is connected up again and repeat the write operation. The ECU will

be left in a state where it wonít run the engine (until you repeat the write

operation) but it will drop back into its boot loader code and communicate with

the mapping application, waiting for programming instructions.

The research required to get this write cost me many ďbrickedĒ ECUs along

the way, but as I say I had modified a couple of ECUs with sockets for the

EEPROM chips allowing me to remove them and recover them in a stand-alone

programmer each time. I am now confident enough in the code that I have

reversed all the modification on my ECUs and put them back to standard with

permanently soldered EEPROM chips. I do not anticipate ďbrickingĒ any more ECUs

- and if I didnít have the self-belief and confidence to use it on standard

ECUs then how could I expect others to?

Iíve built multiple layers of error recovery into the software. If the ECU

rejects any messages or sends inappropriate or corrupted responses (which can

be caused by noise pickup on the power supply or communication lines) the

software repeats the message or takes other recovery action as necessary. If

the ECU stops responding altogether it attempts to reboot it and continue. Even

if it gets into a state where you need to power the ECU off and on again to get

it talking again, you should just be able to hit the ďResumeĒ button and it

will pick up where it left off, whether reading or writing.

NB: Turning off the ignition may not be enough to power off the ECU.

Normally the ECU continues to run for some minutes after the ignition is turned

off. In a Rover it would be monitoring engine bay temperatures and running the

fans. If the ECU functionality is compromised, it may even continue to run

indefinitely. If you want to be sure to power the ECU off fully, either pull

the 30A ECU fuse for a couple of seconds or briefly remove the smaller of the

two connectors from the ECU by sliding the lock outwards.

For some reason the ECU is quite flaky whilst reading data, every now and

again it seems to just ignore a message or respond with complete gibberish. My

code works around all of this the vast majority of the time and from the user

end you wouldnít know it was happening (thereís a little red ďRetryĒ icon at

the bottom of the screen that flashes each time it has to recover from an error

just to give an idea of when itís having problems, but thatís all you see).

Luckily it seems to be rock solid whilst writing. Iím not 100% sure why, I

think some of it is because in a programming diagnostic session it drops back

into the boot loader code and isnít trying to run engine management at the same

time (more information below). One way or another, the good news is that whilst

actually making changes to the memory contents it really does seem to be robust

and reliable and everything goes to plan if it isnít externally interrupted.

Errors, Cancel & Resume

Whenever it is working on a long running process, such as reading from or

writing to the ECU, thereís a ďCancelĒ button enabled. You can click this to

cancel the operation. As mentioned above, I really wouldnít cancel a write part

way through unless there was an emergency, it will leave the ECU in a

non-running state and thereís a small risk of it being too unhappy to be

recoverable. Cancelling a read or verify at any time is fine. And any time you

cancel a read, write or verify thereís a ďResumeĒ button enabled which allows

you to pick up where you left off. This is robust an

reliable, even if the ECU has been shut down or rebooted in the meantime. The

ďResumeĒ button will also pick up an operation that stopped because of an

error. So for example if the ECU just stopped responding half way through a

long read, you can reset it and resume without starting again.

Supply Voltage

Sites on the Internet seem to suggest that you should never try to reflash

any ECU at anything other than 13.5V. This obviously precludes flashing the ECU

in the car, as you canít do it with the engine running and the battery voltage

alone will be well below that. The memory chip itself needs 12V on some pins

whilst flashing, Iím not sure if this is internally generated or whether it

just uses the external supply, but Iíve tested flashing ECUs with supply

voltages from 10.8V to 14.0V and it was fine. If youíre flashing it in the car,

so long as the battery is reasonably healthy it should be happy.

OK SO THATíS ABOUT AS FAR AS YOU NEED TO GO IF YOU JUST WANT TO USE THE

TOOL, THE REST IS THE GEEKY BIT ABOUT HOW IT ALL WORKS INSIDE!

Cracking this has been an interesting challenge for me, to say the least.

Itís been a slow process of unpicking a web of connections. Usually cracking

one part leads to further understanding which unlocks the next part.

Thereís no specific documentation of MEMS3 that I could find. To some

extent it does adhere to common standards, but not fully. Itís all the places

where it deviates from any common standard or where there is no standard which

proved most challenging.

Iíve had to work all of these things out from first principles and

intuition. The information below is based on my own research and is correct to

the best of my knowledge, but Iím just finding my own way through things so it

may or may not be absolutely accurate. I've will probably have used different

terminology and described things from a different perspective to that of people

who may have been involved with MG Rover development. I havenít covered all of

the details or this would turn into a very long read, just some of the more

interesting key points.

A lot of the development work has proceeded by making working hypotheses

and then testing these on ECUs. I many cases they have proved to be

misunderstandings and some of my current state of understanding may not be

absolutely correct but it has formed the basis of a working model of the ECU

which has allowed me to achieve my current objectives.

Some of the methods I've used include:

∑

Sniffing protocols. I've used various different techniques to sniff the messages sent between

other tools and the ECU.

∑

Disassembling ROM code. I've disassembled code inside the ECU EEPROM and code in other tools which were

able to talk to the ECU to find out how things were done. In particular this

was necessary in cracking the seed-key security mechanism. See the Seed Key

Algorithm section†

below.

∑

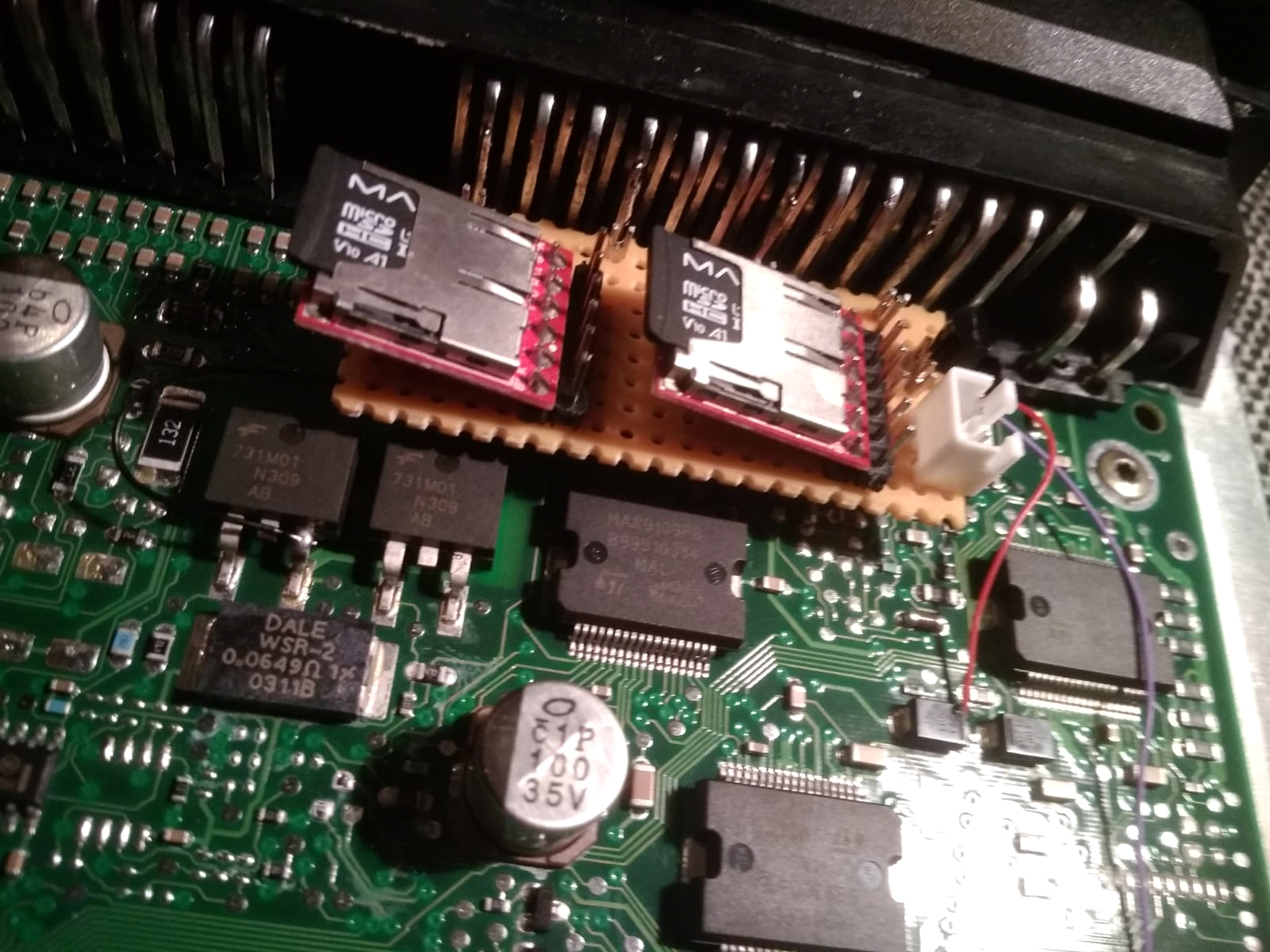

Modified development ECUs. I added various features into a number of ECUs including socketed EEPROM

chips and multi-protocol data loggers to record the communications with the ECU

under various different conditions. I used data loggers based on the SparkFun

OpenLog device but I rewrote some very specific Arduino code for them to allow

them to log a lot of details of the ECU communications, timing etc.

∑

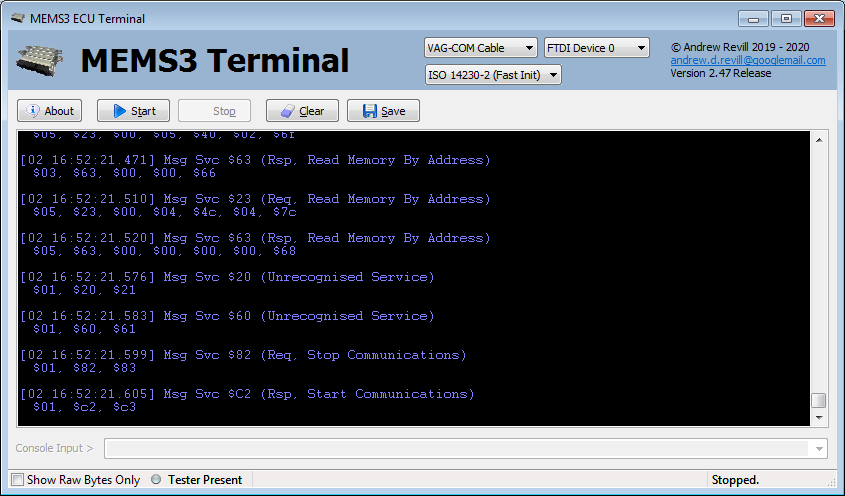

MEMS3 Terminal. Along the way I developed my own terminal application which was capable of interception,

logging and decoding communications with the ECU. This was also capable of

reading and decoding the log files from the development ECUs described above.

It also allowed me to key in messages and talk to the ECU directly.

∑

Modified FTD2XX.dll. A lot of tools which are capable of communicating with

the ECU use hardware based on the FTDI chipset (as does my application). As

these are always compiled Windows executables it's very hard to see what they

are doing internally. But I found that the FTDI driver DLL was a convenient

weak point to attack. Basically I wrote my own version of the DLL. It didn't do

a lot, it just declared all of the same functions as

the original DLL, loaded the original DLL in the background and passed all of

the function calls straight through. But that meant that I was able to add code

to any of my wrapper function to log calls and results. I was also able to add

an inter-process communication pipeline to the terminal program described

above, meaning that all communications with any FTDI devices system-wide would

be reported to and decoded by the terminal in real time. It even allowed me to

intercept specific calls and modify them. But the most interesting thing it did

was to allow me to load any other tool which could communicate with the ECU in

my debugger (by debugging the DLL, with the tool I wanted to debug set as the

host process). This meant I could set breakpoints on calls and then work

through what it was doing at the time, what it would do with the value returned

etc.

Protocols

The communication protocols used by the ECU are very similar to a number of

standard but it doesn't seem to adhere to any of the strictly. I seems to support at least three different protocols.

1.††††††††††† ISO 9141-2. This is

mostly used for communications with OBDII scanners. It operates at a speed of

10400 baud with a specific "slow-initialisation" signal used to start

communications.

2.††††††††††† A native protocol which

uses a lot of KWP2000-type messages but a different addressing scheme. This

operates at a speed of 9600 baud. It has similarities with protocols used by

BMW at the time. There is no particular out-of-band initialisation signal. My

guess is this is the protocol primarily used for commination with the Rover

Testbook suite of internal diagnostic tools. I have referred to it as

"Rover BMW 9600 Baud" in my application. When the ECU first boots up,

in the absence of any special initialisation signal, this is the protocol it

uses.

3. †††††††† ISO 14230-2 / KWP2000.

This protocol seems to adhere more closely to the standards. It operates at a

speed of 10400 baud with "fast-initialisation" signal used to start

communications. Once the ECU has received the initialisation signal for this

protocol, there is no way to switch back to the native protocol other than

resetting the ECU.

In practice I found that either the native protocol or ISO 14230-2 worked

well for reading or writing. The ECU seemed to support all required operation

under both protocols both when running the firmware code or

when dropped back into the boot loader. The usual ISO 9141-2 however seemed

less reliable and I had some difficulty generating an acceptable "slow

initialisation" signal over the FTDI cable. Despite using bit-blatting

techniques and confirming with an oscilloscope that the signal and start of

communications seemed to be exactly the same as those generated by OBDII

scanner, it seemed to be unreliable and the signal was often not recognised.

Once I realised that the ECU supported everything I

needed in either of the other two protocols I decided not to waste any more

effort in ISO 9141-2, which is no longer supported by my tool.

Memory Map

MEMS3 uses a 29F200 EEPROM chip. Specifically it uses an AMD

AM29F200BT-90SE variant. This is mapped into externally accessible address

space (as seen by OBDII) at base address $100000, meaning that the different

sectors of the EEPROM appear at the addresses shown below.

†Sector Size††††††† Address Range† Used For††††††††††††† ††

SA0††††††† 64KB††††† $100000 - $10FFFF†††††††††† Boot

Loader†††††† ††

SA1††††††† 64KB††††† $110000 - $11FFFF†††††††††† Firmware†††††††††††† ††

SA2††††††† 64KB††††† $120000 - $12FFFF††††††††††††††††††††††††† ††

SA3††††††† 32KB††††† $130000 - $137FFF††††††††††

†††††††††††† †††

SA4††††††† 8KB††††††† $138000 - $139FFF††††††††††

†††††††††††† †††

SA5††††††† 8KB††††††† $13A000 - $13BFFF††††††††† Coding† ††

SA6††††††† 16KB††††† $13C000 - $13FFFF†††††††††† Map††††††

Each sector of the EEPROM can only be erased as a whole. Without erase a

sector (which sets every byte to $FF or binary 11111111, logical 1's can only

be programmed to logical 0's and not the other way around, so it is not really

possible to write arbitrary data to a sector without erasing the data in the

area to be written first, and this means erasing the whole sector.

Interestingly the "BT" in the chip designation means "Boot Block

at Top" - so the small 16KB sector SA6 at the top of memory is intended to

hold boot loader code, which would be a small application whose sole job is to

communicate with some external tool to allow the contents of the rest of the

EEPROM to be loaded. In MEMS3, this sector SA6 is used for the map data which

it relatively small and the bottom 64KB sector SA0 is used to the boot loader

code. The next 4 sectors SA-SA4, 64KB + 64KB + 32KB + 8KB = 168KB are used for

the firmware code. The next 8KB sector SA5 is used for what I have called

Coding - this basically includes the VIN code and the Part Variant. Of the 8KB

available this sector, only 14 bytes (VIN) plus 6 bytes (Part Variant) appear

to be used.

As far as I can tell the ECU only provides routines to erase the firmware

and map sectors. So the boot loader code is permanent and cannot be changed

without corrupting it. This makes sense as the boot loader code is what is

executing when loading firmware or map data; overwriting the boot loader while

it was running would not make sense. The same is true of the Coding data, so it

is not possible to write a new VIN code or Part Variant code to the ECU. This

is probably for security, the original VIN number being indelibly written to

the ECU. The other possibility of course is just that I haven't been able to

track down the routines to erase the coding data. This doesn't seem to be a

significant restriction, as any version of the boot loader seems to work

happily with my tool and will load any firmware version. The boot loader code

isn't involved in running the engine at all, so once the firmware has been

loaded and is running the older boot loader is irrelevant, and the VIN and Part

Variant code are informational only.

The boot loader version on an ECU seems to be consistent across ECUs with

the same part number. So for example an early VVC ECU NNN000100 will always have

boot loader version BOOTP030 and a later VVC ECU NNN000160 will always have

boot loader version BOOTP033.

Runtime & Adaptations

Runtime data such as DTCs, adaptations and immobiliser coding are stored in

a separate 93C66 serial EEPROM chip. This doesn't appear to be externally

addressable; it doesn't appear as memory addresses mapped into the memory space

accessible to OBDII commands. I believe data here will be read and written

using higher level OBDII commands used to request diagnostic information, or to

request or set data by local identifiers. I haven't been able to track all of

these down, but I have managed to provide workarounds which seem to be

perfectly adequate. So for example when writing a new map I clear the existing

adaptation and when writing new firmware I clear the immobiliser coding and

allow the ECU to re-learn the code from the immobiliser. I haven't had any

issues using these workarounds in testing.

Checksums

The firmware and map areas of the EEPROM are protected by checksums. This allows

the ECU to verify that any data loaded has not been corrupted during transfer.

It also prevents anyone who doesnít know the checksum algorithm from being able

to modify the data.

The idea is that some mathematical operation is performed across all the

bytes in the area covered by the checksum to give a number, which is then

stored in the data. The ECU is then able to perform the same mathematical

operation on the data in its memory and compare the number it gets to the

number stored. If they are the same, the data is assumed to be unmodified. If

they ae not the same, the data must have been modified and is rejected.

Checksums are traditionally added to the end of a data block, so the first

place I looked was the last two bytes of each block, but in each case these

just contained $FF, $FF indicating unused space at the end of the block.

I tried various different checksum algorithms but nothing matched; the main

issue I had was working out which bytes in the data were the checksum. Then I tried

just adding up all of the numbers in the block, first as 8-bit bytes and then

as 16-bit words, and a pattern emerged across the ECUs. For any given block

(i.e. firmware or map), the answer was the same in every ECU I looked at.

So for example, for the firmware area, the 16-bit sum of the 86,016 16-bit

words (high byte first) at hexadecimal addresses $110000/1 to $139FFE/F is

always equal to $04FB.

This gave me the checksum algorithm. Somewhere in the block there are two

checksum bytes which get to $04FB minus the sum of all of the other pairs of

bytes. Thereís no way to work out which two bytes, as if you think about it

EVERY pair of bytes will be equal to $04FB minus the sum of all of the others.

But it doesnít matter, because Iím also free to adjust any two bytes I chose.

At the end of each block there is a large amount of unused space as the

contents of the blocks are quite a lot smaller than the EEPROM segments

allocated to them. So I can rely on the fact that the last few bytes of the

block will be unused and safely replace two of the with

$04FB minus the sum of all of the others and the rule will be satisfied.

Iíve tried modifying data and correcting the checksums in this way and the

ECU happily accepts the new firmwares and maps.

My application now checks the checksums for the firmware and map on loading

a file, saving a file or writing to the ECU and offers

to correct them automatically if they are incorrect. On writing to the ECU it

checks them, offers to correct them and refuses to write to the ECU if they are

not corrected, as the ECU would not run with incorrect checksums.

Seed Key Algorithm

The ECU is protected by a seed key security system. When you want to gain

security access, the ECU gives you a 16-bit number called the seed. You have to

perform a (secret) operation on this to work out the corresponding key, and

give that back to the ECU. The idea is that only Rover know the details of the

operation to be performed and, like a good hash function, the output numbers

give very little clue as to the calculation. So you canít for example record a

programming session and make a note of the key used, because next time the seed

will be different and an entirely different key will be required.

To work this out I had to reverse engineer it by disassembling machine code

routines in the ROM and in other programming tools.

As MG Rover are now long gone, I donít have any moral qualms about

publishing the seed key algorithm that I discovered, without which you cannot

unlock and maintain our ECUs. Here it is in full, written in Pascal (I used

Delphi for the development of the application which is Pascal based). You could

code it in any language you like. It takes a 16-bit seed and returns the corresponding† 16-bit

key:

function SeedToKey(ASeed: Word): Word;

var

† I: Integer;

begin

† Result:=0;

† I:=1;

† if Odd(ASeed shr 15) then

††† Inc(I, 8);

† if Odd(ASeed shr 7) then

††† Inc(I, 4);

† if Odd(ASeed shr 4) then

††† Inc(I, 2);

† if Odd(ASeed) then

††† Inc(I);

† for I:=I DownTo 1 do

††† begin

††††† Result:=(((ASeed shr 1) and $FFFE)

†††††† or Ord(not(Odd(ASeed shr 13) and

Odd(ASeed shr 3))))

†††††† and $7FFF;

††††† if Odd(ASeed shr 9) xor Odd(ASeed

shr 8) xor Odd(ASeed shr 2) xor Odd(ASeed shr 1) then

††††††† Result:=Result or $8000;

††††† ASeed:=Result;

††† end;

end;

Boot Mode, Diagnostic Sessions

One thing which originally puzzled me was how to get the ECU into boot mode

to allow the firmware to be overwritten. I was originally assuming that there

was some combination of voltages applied to pins when booting which caused the

ECU to enter boot mode and run the boot loader code rather than the main

firmware, but in the end the answer was a lot more simple and convenient; there

are a number of different "Diagnostic Session" types that you can

request, and combined with the right security privileges, requesting a

programming diagnostic session exits the firmware and runs the ECU in the boot

loader code. You can recognise that the ECU is in boot mode because although

communications with the ECU remain normal, none of the engine management

functions are running. The fuel pump doesnít prime, the IACV doesn't chatter as

it usually does and the engine will not run.

Routines

The ECU has number of pre-defined routines in EEPROM that you can execute

with a command to "start routine by local ID". Some of these routines

execute quickly and return a positive or negative result almost immediately.

Some of them however execute for several seconds, such as the main firmware

EEPROM erase routine. These return a pending result immediately and a further

positive or negative result on completion. Figuring out the IDs and parameters

required for these routines was one of the challenges of cracking this.

Maps

The upper 16KB sector of the EEPROM contains the tune file or map. This

consists largely of a number of tables. These are generally referred to as 2D

or 3D tables, although more correctly these are 1D or 2D arrays of numbers (the

third dimension being the axis on which the actual table numbers are plotted on

a 2D line or 3D surface chart). Even for the same firmware version, the

addresses of the maps in memory vary between different ECUs and map files. The

main firmware locates each table by looking up the address in a master table

index. This master table index varies in address in different firmware versions

and I can't find any kind of "index of indexes" that points to it, so

my guess is the index address is just a constant baked into the firmware code

at compile time. The index however easily located as it sits alone above

everything else towards the top of the map file address space, so any block of

valid table addresses which follows an unused block of $FF space will be the

master table index.

Most of the rest of the map space consists of tables in the same format,

stacked one after another with no gaps between them. Oddly however not all of

these tables are pointed to by the master index. Most of the unindexed tables

seem to contain junk data such all zeros. My guess is that these tables are not

used by the firmware as it has no way to address them directly (it could be

that there are a number of tables used as a set, which always follow each other

in memory, and so the ECU only needs to be able to index the first one and then

walk along them as there are no gaps, but I doubt it looking at the contents of

the unindexed tables. Quite why the unused tables are still there but not

indexed I have no idea, it must be a quirk of the original map compiler used by

Rover.

Future Plans

I'd like to build up a library of Caterham maps, especially the

"special editions" such as Supersport ECUs. This would allow any of

these ECUs to be recreated using stock cheap MEMS3 ECUs off eBay. I would

backup complete firmwares in the library as I believe this would also cover any

special cases where the firmware may have been specifically modified, such as

they code in a Supersport ECU which repurposes the air conditioning clutch

output as a shift light.

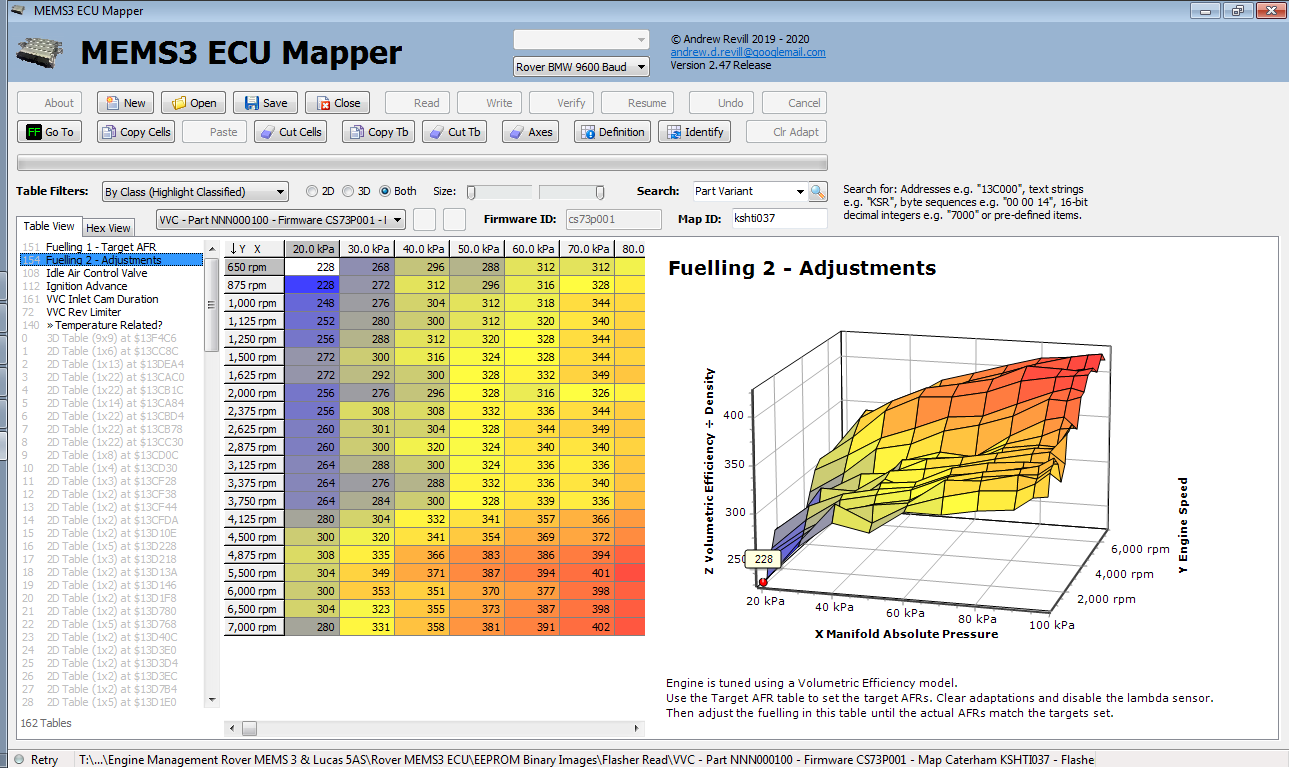

My ultimate goal is to make the MEMS3 ECU properly remappable. To be

honest, by the time I've got round to writing this up I've pretty much already

done it. I've already got full control of the target AFRs, open/closed loop

control, fueling adjustments, ignition timing, overrun pop and crackly, idle

air control valve and rev limiter. On VVC engines I've also got control of the

VVC mechanism sorted. I think I've pretty much covered all of the key

parameters you would want to adjust when remapping the ECU for a modified

engine.

I've already been able to adjust all of these parameters consistently and

flash the modified maps back to my car with the expected results (rev limited

to 3K it did feel a bit sad!).

The mapping application is a lot more comprehensive, complicated and

flexible but is built on top of the flasher tool described in this post. I'm

still working on tracking down more parameters and I need to put some finishing

polishing touches to my remap application and there will be another write-up

soon, but here's a teaser ...