Remapping the Rover MEMS 2J and Land Rover Td5 MSB ECUs

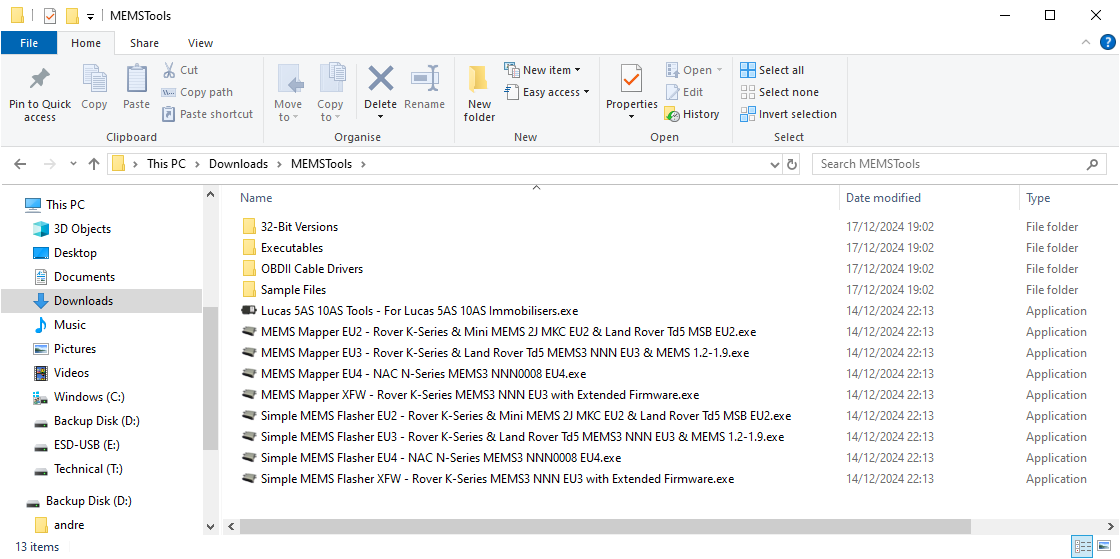

Download

Link: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

After many months of development work, I have recently completed a major upgrade to my MEMS Tools suite. This now fully supports reading / writing / remapping of the Rover MEMS 2J and Land Rover Td5 MSB ECUs. These ECUs were previous not writeable over OBDII. With a small modification to the ECU itself, they become readable and writeable using MEMS3 Mapper with programming and customisation functionality almost exactly equivalent to MEMS3.

Overview

The previous version of my tools suite was known as MEMS3 Tools, comprised of the MEMS Flasher application for reading and writing ECUs and the MEMS3 Mapper application for remapping work, supporting custom firmware patches such as dual map with live switching. Later versions of MEMS3 Tools included limited support for MEMS 2J and Td5 MSB. They provided all of the usual maintenance and servicing tools (similar to the Rover T4 system), allowed the ECU ROM to be read and dumped to a file, and also allowed the ECU map to be read and displayed, however the map display was achieved by converting the map into a MEMS3 format and the map could not be meaningfully edited and could not be written back to the ECU.

The new version of my tools suite is known as MEMS Mapper and has EU2, EU3 and EU4 versions of all of the main applications. So, we have MEMS3 Flasher EU2, MEMS3 Flasher EU3, MEMS3 Flasher EU4, MEMS3 Mapper EU2, MEMS3 Mapper EU3 and MEMS3 Mapper EU4. The EU4 versions of the applications support the MG TF LE500 NAC N-Series ECUs. The EU3 versions of the applications are the “general purposes” versions and support the Rover MEMS3 and the Land Rover Td5 NNN ECUs as before as well as providing basic (live diagnostics and data, maintenance and servicing) support for MEMS 1.9 / 1.6 / 1.3 and 1.2 (as for the earlier MEMS3 Tools releases).

The new EU2 versions of the applications support the Rover MEMS 2J and Land Rover Td5 MSB ECUs, which are no longer covered by the EU3 versions. The EU2 versions provide full native support and work with the EU2 ECUs in almost exactly the same way as the EU3 versions work with the Rover MEMS3 and Land Rover Td5 NNN ECUs. They correctly reflect and understand the memory maps of the EU2 ECUs. Maps can be read, edited and written (with small modifications to the ECUs as described below). Most of the familiar custom functionality provided by the earlier MEMS3 Tools is now supported on the EU2 ECUs using MEMS Mapper EU2 application, including:

- Read / Write / Erase Firmware & Map

- With Fail-Safe, Resumable, Brick-Proof Writing

- With Bricked ECU Recovery

- Read / Write / Erase Serial EEPROM

- Read & Save RAM & Module Registers

- Read / Write Boot Loader

- Dual Map Switches with Live Switching

- With a Selection of Available Inputs

- Throttle-Based Switch

- Launch Switch

- OBDII-Based Switch

- Immobiliser Delete (Map & Firmware Methods)

- Seed Key Unlock

- Injector Swaps

- MAP Sensor Swaps

- Flywheel Trigger Pattern Swaps

Nearly

everything works exactly the same as on MEMS3 with MEMS Mapper E3. One small

difference is that in EU2 ECUs the map (and sometimes maps, as there can be two

maps as supplied from the factory) is at an arbitrary address within the same

ROM sector as the firmware; for this reason, the firmware and map cannot be

read from and written to the ECU separately as with MEMS3, but are always

written together as a single operation. There is only one checksum and

verification procedure in the ECU which covers both the firmware and the maps.

Architectural Changes

When I compared

the EU2 architecture of the Rover MEMS 2J and Land Rover Td5 MSB ECUs with

their EU3 descendants the Rover MEMS3 and Land Rover Td5 NNN, it was clear that

there were two basic problems which would need to be overcome in order to

render the EU2 ECUs fully remappable:

- The ROM chips used in the EU2 ECUs (AT27C1024)

were One-Time-Programmable. They were flashed with the firmware and map at

the factory and could not then be erased or rewritten.

- There was no separate boot loader. The EU3 ECUs

has EEPROM chips that were divided into sectors and where individual

sectors could be erased leaving other sectors intact. This allowed one or

more sectors to be allocated to a boot loader program which was

independent of the main firmware and was able to facilitate programming of

the firmware and map. This allowed the firmware to be erased under the

control of the boot loader, leaving the boot loader intact and able to

communicate to load a new firmware.

For point (1), after some research I came to the

conclusion that there was one single EEPROM device type which met the following

requirements:

- 1 Mbit EEPROM

- Pinout Compatible

with AT27C1024

- 5V-Only,

Programmable In-Circuit

- Sector Structure Compatible with Boot Loader

This was the

AT29C1024. It’s a less well-known and less-used chip than the AT27C1024. It is

now obsolete from the manufacturer Atmel (as are most of the chips of that

vintage) but still readily available by the thousand from Chinese obsolete

silicon specialists selling through e.g. AliExpress. Not many of the bench chip

programming tools support it, but the XGecu T56 does, with a suitable PLCC44 to

DIP44 adapter. It is a drop-in replacement for the AT27C1024 in this

application. It can be programmed in-circuit with the available 5V supplies

only. In addition, it has a very granular sector structure, with each block of

256 bytes (128 words in 16-bit mode) being a separately erasable and writable

sector or page.

For point (2) it was clear I was going to have to write a

stand-alone boot loader from scratch. So that’s what I did! It’s written

directly in 68000/CPU32 assembly language and occasional binary machine code.

It supports standard ISO14230 / KWP2000 communications (with a subset of the

full protocol message set implemented as required, but following all standards

for initialisations, message formatting, timings, timeouts etc.) as for the

standard EU2 and EU3 firmwares, meaning that the PC end could talk to an ECU in

the same way without having to know if it was running the boot loader, a stock

firmware, or a firmware running under the boot loader. The standard firmwares

need a small number of modifications patching in, described in detail later in

this article, but MEMS Mapper EU2 is able to apply all of these patches

automatically on writing. The memory layout is modified to place the boot

loader vector table at the start of the EEPROM where the firmware vector table

would normally reside, meaning that the ECU initially boots up into the boot

loader and this can then decide whether or not to jump into the firmware. See Boot Loader

Technical Details below for further information.

ECU Modifications

Both the Rover

MEMS 2J and Land Rover Td5 ECUs need to me modified slightly to meet the

architectural requirements described above. The modifications required are

described in the following articles. These articles also ship with MEMS Tools

and can be displayed as help from the ECU information dialog within the MEMS

Mapper EU2 application:

Using MEMS Mapper EU2

Reading maps from unmodified ECUs,

reading and writing maps from and to modified ECUs, editing of maps and the

installation of firmware patches all proceed almost identically to using the

MEMS Mapper EU3 with a MEMS3 ECU.

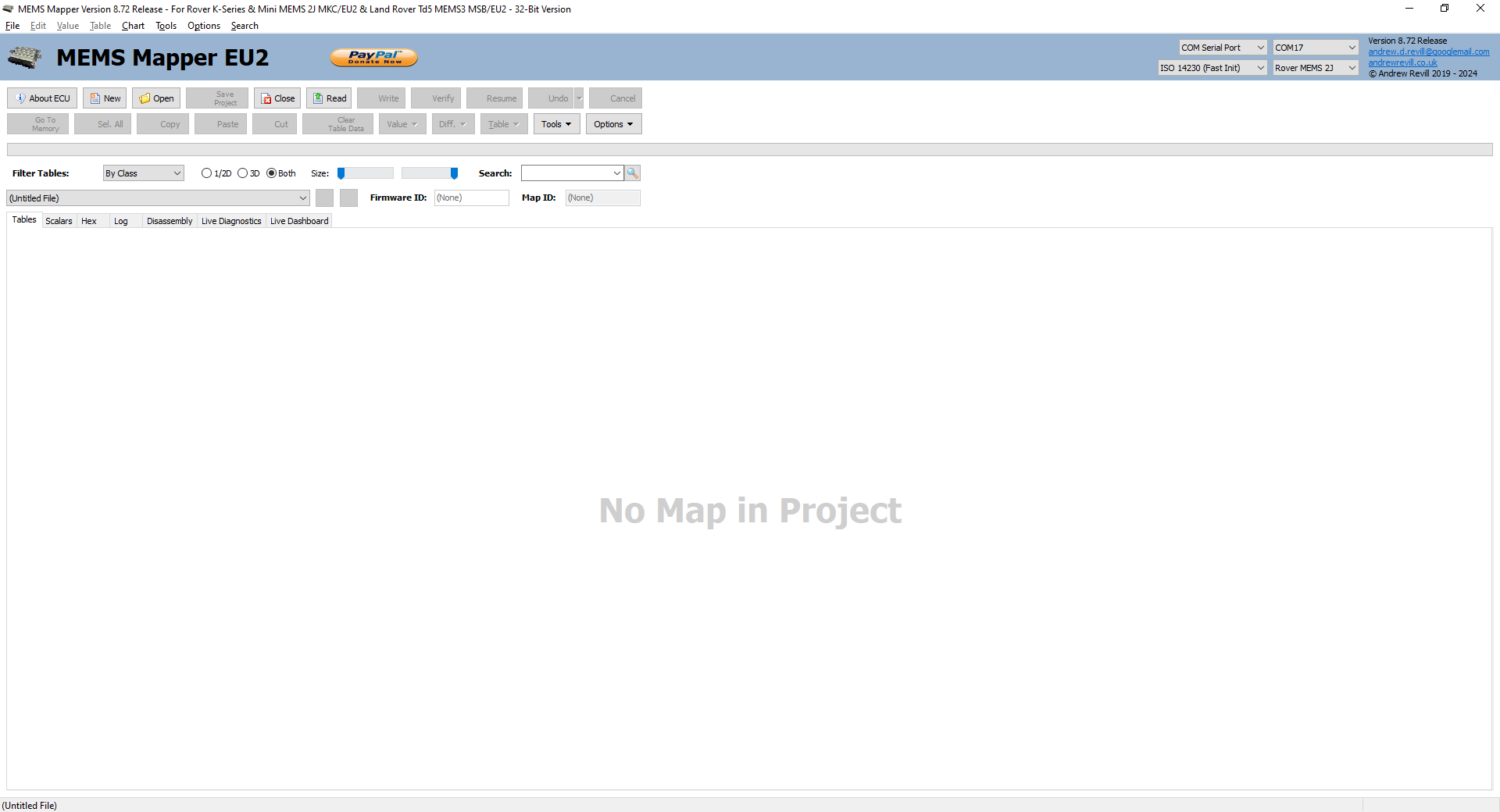

The MEMS2 Mapper EU2 main window is also

almost identical to the familiar MEMS Mapper EU3 main window:

Click Read to read the firmware

and map from an ECU (either a stock EU2 ECU or a modified remappable ECU, they

behave identically under Mapper EU2 when reading).

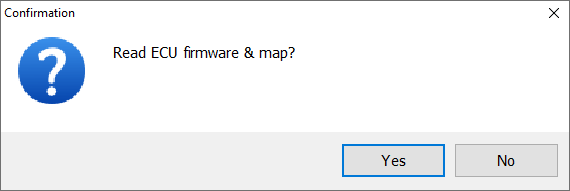

Click Yes. There is no separate

option to read Firmware & Map or just Map as in MEMS Mapper EU3. Thay are

always read together under EU2. EU2 ECUs only support 1x Speed reading and

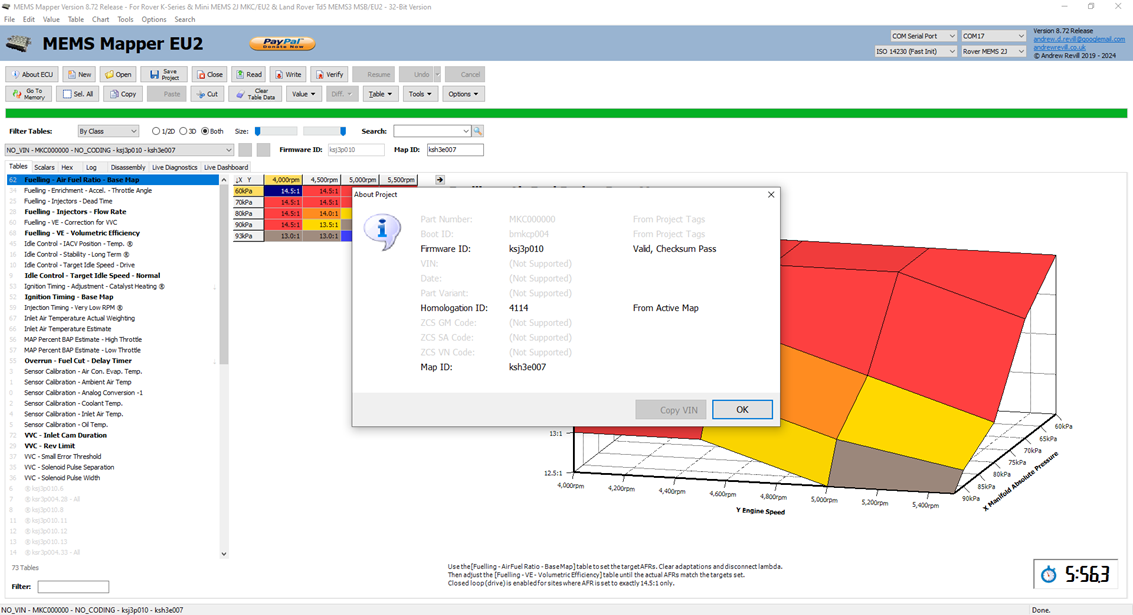

writing, so there are no speed options (the K-Line appears to be much more heavily

filtered and higher Baud rates are filtered out as noise). A successful read

will be confirmed with an About Project dialog and the map and firmware

data will be displayed as show below:

Once you have read the ECU you can save

the file, edit tables, edit scalars etc. freely as in MEMS Mapper EU3.

When you are ready to write the modified

file back to the ECU (only for modified remappable ECUs, this WILL NOT WORK

for a stock EU2 ECU), click Write.

If the file was read from a stock ECU, it

will need to be patched for compatibility with the boot loader. MEMS Mapper EU2

can apply all of the required patches automatically on write. It will normally

be able to find all of the patch addresses and all of the check boxes should

show a green tick (don’t worry if ROM Mount in RAM Subroutine Found at:

is blank, this is optional as it is found in some firmwares, particularly Land

Rover Td5 MSB firmwares, and is only patched where present – other ECUs use a

different method for mounting the ROM chip which does not need to be patched).

If the file has already been patched, or was ready from a modified remappable

ECU, this dialog will not be displayed. To patch the firmware, click Patch.

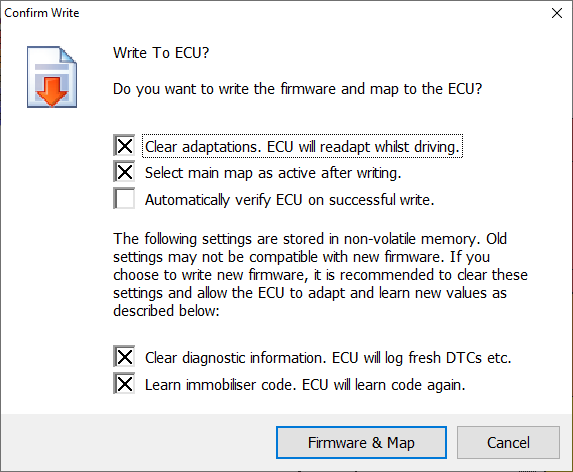

Again, you only have the option to write

the Firmware & Map together under EU2. EU2 ECUs only support 1x Speed

reading and writing, so there are no speed options (the K-Line appears to be

much more heavily filtered and higher Baud rates are filtered out as noise).

The other write options do carry over from MEMS Mapper EU3 though, so you have

the option of clearing adaptation, automatically verifying that the ECU has

been written correctly, clearing diagnostic information and learning the

immobiliser code.

Where an EU2 ECU contains two maps

natively (from the factory, not because of the installation of a map switch

patch) then writing a file with different map addresses can result in an

invalid map offset being stored. This may cause the ECU to select an arbitrary

map, or even the internal NOSELECT map (which is just a default to allow the

ECU to run when no proper engine management map is selected). For this reason,

by default, on writing to the ECU, the first / default map is explicitly

selected. If you want to select a different map after writing, use Tools |

ECU Tools | EU2 Map Selection from the menu.

A successful write will be confirmed with

an About ECU dialog as shown below:

Immobiliser Delete

One request I often get is to delete the

immobiliser functionality on a MEMS 2J. This can be done easily on a modified

remappable ECU with MEMS Mapper EU2.

Read the ECU, edit the immobiliser delete

flag in the project and then write it back to the ECU.

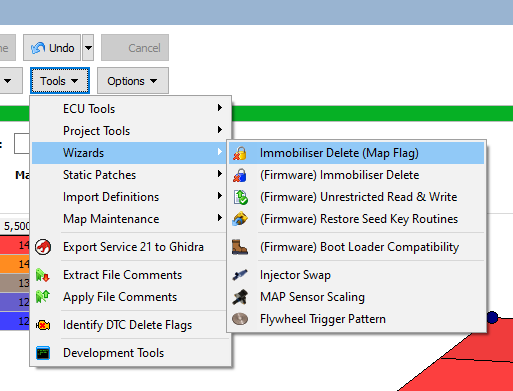

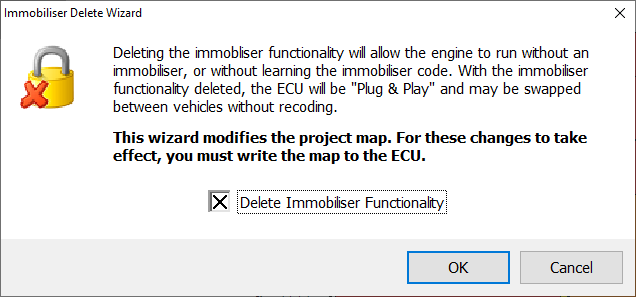

Click Tools | Wizards | Immobiliser

Delete (Map Flag) from the menu.

Check the Delete Immobiliser Functionality box and click OK.

Alternatively, you may edit the scalar Immobiliser

Delete Flag from 0 to 1 in the Scalars tab by hand.

Dual Map Switching Patches

Using MEMS Mapper EU2, Rover MEMS 2J and

Land Rover TD5 MSB ECUs can now be configured to switch between two separate

maps. The switching can be live with the engine running, even under load. The

engine will not even cough or hesitate when switching.

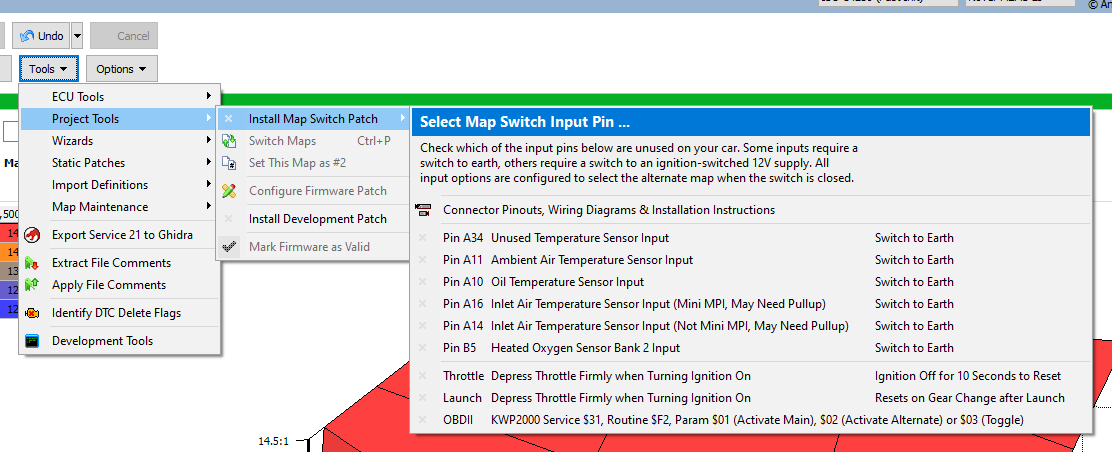

Select Tools | ECU Tools | Install Map

Switch Patch from the menu, the select which available input pin you want

to use.

Different ECUs and different cars use

different inputs, so a different selection of inputs may be available on each

car. Choose an input pin which does not have a wire connected to it on your

ECU. For help with identifying the relevant pins and how to wire a switch to

each one, select Connector Pinouts, Wiring Diagrams & Installation

Instructions from the menu as shown above. The help information is also

available through the following links:

- Connector Pinouts, Wiring Diagrams &

Installation Instructions – Rover MEMS 2J

- Connector Pinouts, Wiring Diagrams

& Installation Instructions – Land Rover Td5 MSB

On ECUs which contains two native maps

from the factory, the map switch patch will switch between them. On ECUs which

contain only a single native map, the map switch patch will install a second

alternate map. To switch between the two maps in a project with more than one

map (natively, or through the installation of a map switch patch), select Tools

| Project Tools | Switch Maps or press Ctrl-P.

Boot Loader Technical Details

The following information is for those who

are interested to read the technical details. You don’t need to know or

understand any of this to use the tool, it’s just background information.

The key to adding a boot loader to the

ECU was to rearrange the memory map in such a way that ECU would boot straight

into the boot loader code, which could then hand over to the firmware code when

it needed to do so, without requiring wholesale modifications to the firmware

code. This meant that the firmware code could not be relocated. But the first

1024 bytes of the firmware consist of a vector table, which contains the

addresses of all of the firmwares exception and interrupt handlers. The first

two entries in the vector table hold the initial stack pointer and the initial

program counter (address of the main entry point to the firmware program). The

ECU boots after a reset with System Integration Module register values such

that the ROM chip is mounted at address $000000 and it reads the initial SP and

PC from there, so I needed to be able to place my own vectors there to force

the ECU to boot into the boot loader.

When booting up, one of the first jobs

the firmware normally does is to remount the ROM from address $000000 to

address $100000. This allows it to place RAM at $0000, which allows RAM to be

addressed with word addressing mode which makes the firmware code more compact

and efficient. In doing so, it needs to tell the processor that the vector

table has moved. It does this by settings a Vector base Register (VBR) to the

new address of the vector table at $100000. All access to the vector table is

for interrupt and exception handler addresses is then done relative to the

address in VBR. The VBR is only ever assigned once during the firmware startup

process. By patching that one instruction, I could move the firmware vector

table to a new address and point the VBR to it and the firmware would run

completely normally, oblivious to the change. I was then able to place the

vector table for the boot loader in the original location. That contained the

correct initial SP and PC for the boot loader.

This required that the boundary between

the boot loader vectors and the firmware code at $100400 was a sector boundary

of the EEPROM chip in order to allow the firmware to be erased without touching

the boot loader. Luckily the AT29C1024 has 256-byte sectors and every multiple

of $100 is a sector boundary, so the boot loader vectors occupy the first 4

sectors exactly.

At the very top end of the ROM address

space, in an area that is always unused in all stock EU2 ECUs (the ROM chips

are larger than the firmware and maps combined, even when two maps plus

NOSELECT are present), I then allocated 6kB to the boot loader code at

$11E800-$11FFFF.

Immediately before this at

$11E400-$11E7FF I placed the relocated firmware vector table.

This left the largest possible single

block of contiguous free space between the end of the NOSELECT map and the

start of the firmware vector for use by custom patches. It meant that the ROM

sectors allocated to firmware formed one contiguous block from $100400-$11E800

and this could be erased without touching either of the boot loader areas which

consisted of the sectors $100000-$$1003FF (vectors) and $11E800-$11FFFF (code).

When MEMS Mapper EU2 detects that a

project has been patched for compatibility with the boot loader, it blocks out

the boot loader address ranges and does not write them to the ECU. Furthermore,

it insists that they contain only $FF bytes before allowing the project to be

written to the ECU (see Checksum Technical Details below). When reading

an ECU, MEMS Mapper EU2 checks on completion whether the project has been

patched for compatibility with the boot loader and if so, it discards the data

read in the boot loader address ranges.

I had previously developed a full

background, interrupt-driven communications system in 68000 assembly language

for use in custom RAM agents on MEMS3. Because code size was critical in this

application due to available RAM limitations, this was not fully ISO14230

compliant. For the boot loader I really needed a communications suite that

would support a subset of the ISO14230 message set, but it needed to support

those messages and behave in all other ways identically to the firmware

implementation of ISO14230. This would allow MEMS Mapper EU2 to communicate

with an ECU without having to know in advance whether it was running firmware

or just the boot loader. It would also allow the ECU to switch seamlessly

between the firmware and the boot loader when a Programming diagnostic session

was requested with no change in communications protocol required. So, I

upgraded my existing library to allow it to be assembled with an ISO_COMPATIBLE

directive. When this directive was not specified, the library behaved as before

and was compatible with the existing RAM agents and other existing use cases.

When this directive was specified, the following main changes were implemented:

- Support

for ISO14230 Fast Initialisation sequence. The existing custom library behaved more

like the native Rover / BMW mode, in that it was “always on” and did not

require any kind of initialisation sequence to start communications. ISO

mode requires a very specific and precisely timed sequence including

out-of-band signalling outside of the normal UART signalling at the

current Baud rate. This initialisation is important in environments where

more than one device may share the K-Line as only one device should be

initialised and communicating at any one time, with other devices

remaining silent. The boot loader implementation follows the ISO14230

standard closely and validates all timings and byte exchanges. When

uninitialized, the boot loader ignores incoming message and does not send

responses.

- ISO14230

initialisation timeout. As above, the

existing custom library behaved more like the native Rover / BMW mode, in

that it was “always on” and did not time out after a period of inactivity.

The timeout behaviour is important as it provides a mechanism for a device

to return to the uninitialized state after communications are complete,

allowing a different device to be initialised. The boot loader

implementation times out the ISO initialisation state after 10 seconds of

inactivity. The timeout applies during the initialisation sequence too, so

if an initialisation sequence commences but is then interrupted or

abandoned, after 10 seconds the ECU will return to the fully uninitialized

state and wait for the start of a new initialisation sequence.

- ISO

compatible message structure, format bytes, checksums etc. As above, the existing custom library

behaved more like the native Rover / BMW mode and used a fixed format byte

($C7 instead of $B8 – “Caterham 7 Protocol”!) followed by a length byte.

ISO provides for the length of short messages to be encoded into the

format byte and the boot loader needed to be able to send and receive

messages following this convention. In addition, ISO protocol required a

SUM message checksum in place of XOR used by the existing custom library.

With these changes, the custom

communications library in the boot loader in ISO mode appeared identical to the

firmware when in communication with MEMS Mapper EU2. However, only the subset

of the standard ISO messages required to support the boot loader function were

then implemented in the boot loader code alongside some custom messages as

described in the table below:

|

Ident |

Service |

Status |

Description |

Comments |

|

SVC_DIAGNOSTIC_SESSION_CONTROL |

$10 |

ISO14230 |

Used to start General (Firmware) or Programming

(Boot Loader) diagnostic sessions. |

The firmware is patched such that requesting

a Programming session using this service resets the ECU into the boot loader

which then sends the message response. |

|

SVC_ECU_RESET |

$11 |

ISO14230 |

Use to reset the ECU. |

|

|

SVC_READ_ECU_IDENTIFICATION |

$1A |

ISO14230 |

Used to read the part ECU part number. |

The firmware implementation provides

for additional identification information but the boot loader only needs to

support the part number. |

|

SVC_READ_DATA_BY_LOCAL_IDENTIFIER |

$21 |

ISO14230 |

Used to read one of a defined set of

live data records from the ECU. |

The boot loader only implements specific

fields within a subset of the records as required. It returns the Firmware ID

(16-byte format) field in record $0E, the Firmware ID (8-byte format) and Main

Map ID in record $32 and the Boot ID in record $33. |

|

SVC_READ_MEMORY_BY_ADDRESS |

$23 |

ISO14230 |

Used to read a block of memory from the

ECU. |

|

|

SVC_SECURITY_ACCESS |

$27 |

ISO14230 |

Used to implement a seed-key security

access algorithm. |

The boot loader does not actually

require seed-key security, but needs to handle the messages for compatibility

as the firmware does require it. The boot loader always replies with $0000 “already

authorised or authorisation not required”. |

|

SVC_REQUEST_DOWNLOAD |

$34 |

ISO14230 |

Used to request to write a block of

memory to the ECU. |

|

|

SVC_TRANSFER_DATA |

$36 |

ISO14230 |

Used to transfer data when writing to

the ECU. |

|

|

SVC_REQUEST_TRANSFER_EXIT |

$37 |

ISO14230 |

Used to end a transfer of data when

writing to the ECU. |

|

|

SVC_CUSTOM_ERASE_FIRMWARE |

$91 |

CUSTOM |

Used to erase the firmware. |

Routines such as this would normally be

implements with service $31 SVC_START_ROUTINE_BY_LOCAL_ID. This would however

require extensive firmware patching so separate custom messages are used

instead. |

|

SVC_CUSTOM_ERASE_SERIAL |

$93 |

CUSTOM |

Used to erase the serial EEPROM. |

As above. |

|

SVC_CUSTOM_PROTECT_SERIAL |

$94 |

CUSTOM |

Used to restore write protection of the

serial EEPROM after writing. |

As above. |

|

SVC_CUSTOM_READ_SERIAL |

$95 |

CUSTOM |

Used to read data from the serial

EEPROM. |

As above. |

|

SVC_CUSTOM_WRITE_SERIAL |

$96 |

CUSTOM |

Used to write data to the serial

EEPROM. |

As above. |

|

SVC_CUSTOM_APPLY_VERIFICATIONS |

$97 |

CUSTOM |

Used to request that the ECU internally

verifies the checksums after writing and applies the verification word if

correct. |

As above. |

|

SVC_CUSTOM_UPDATE_BOOT |

$98 |

CUSTOM |

Used to trigger the internal process of

updating the boot loader once the new boot loader has been written to the firmware

areas and verified. |

As above. |

|

SVC_CUSTOM_READ_ENCRYPTION_KEY |

$A2 |

CUSTOM |

Used to read the encryption key from

the ECU. |

As above. |

Checksum Technical Details

The ECU’s internal firmware code

calculates checksums over the entire ROM space from $100000-$11FFFF. MEMS

Mapper EU2 does not process the areas allocated to the boot loader but needs to

be able to verify the checksum. It needs to be able to process the checksum for

the firmware independent of the contents of the boot loader areas which it is

not aware of. The conflict can be resolved if the checksum for the boot loader

areas alone is always arranged to be the same as the checksum of the same space

filled with $FF bytes. In this case, MEMS Mapper EU2 can calculate the checksum

of the whole ROM with no boot loader and the ECU can calculate the checksum of

the whole ROM with a boot loader and the answers will agree. When producing new

versions of the custom boot loader files, the release process I have developed

corrects the checksum of the boot loader areas to ensure that the above

condition is always satisfied.

Firmware Patch Technical Details

When writing to an ECU, MEMS Mapper EU2

will check whether the patched for compatibility with the boot loader have

already been applied (in the case of a project read from a modified remappable

ECU, or after selecting Tools| Wizards | (Firmware) Boot Loader

Compatibility from the menu). If not, it will apply the patches

automatically. The following changes are patched onto a stock firmware:

- ROM

Mount in RAM Subroutine – As the

firmware starts up, one of the first jobs it does is to remount the ROM

from address $100000 to address $110000. This process is a bit awkward

because the code which remounts the ROM is being executed by the

microcontroller from the ROM at the time. So as soon as it executes the

instructions that relocates the ROM to the new address range, the next

instruction to be execute immediately becomes unavailable. Interestings,

different ECUs take one of two different approaches to getting around this

problem:

Rover MEMS 2J ECUs take a rather dirty approach:

0000070c 20 7c 00

movea.l #0x10071a,A0 ; Sets up the address of the first instruction

to be executed after the

10 07 1a ; after the ROM is relocated, using its NEW

address, in register A0.

00000712 31 fc 10 move.w #0x1005,(CSBARBT).w ; Set CSBARBT (Chip Select Base Address

Register Boot ROM) to relocate

05 fa 48 ; the ROM to $100000.

00000718 4e d0 jmp (A0) ; This instruction no longer

exists at this address! But it is a single

; word instruction and this

relies on the bus prefetch; the CPU will

; have ready this instruction

ahead of time and still executes it.

; This jumps to the next

instruction at the NEW address to continue.

0010071a 31 fc 00 move.w #0x0,(TRAMBAR).w ; This is the first instruction executed

at the NEW address.

00 fb 04

This is quite a nasty trick but it seems to work. It relies on the fact that

the CPU32 core will already have executed the next bus cycled and pre-fetched

the next pipeline instruction when it executes the CSBARBT assignment to

relocate the ROM. So even though the jmp (a0) will no longer be there at

address $000718 (it will have been relocated to $100718), the CPU will not

notice and it will still be executed correctly. This instruction is a jump to

the next instruction at reh relocated address $10071A and execution then

continues normally from this point.

Land Rover Td5 MSB ECUs take a much cleaner if slightly more long-winded

approach:

00100458 70 07

moveq #0x7,D0 ; Number of words in subroutine

in ROM.

0010045a 20 7c 00

movea.l #0x300000,A0 ; Address of location in RAM.

30 00 00

00100460 22 7c 00

movea.l #0x55c,A1 ; Address of subroutine in ROM.

00 05 5c

LAB_00100466

00100466 30 d9

move.w (A1),(A0) ; Copy subroutine from ROM to

location in RAM.

00100468 51 c8 ff fc dbf D0w,LAB_00100466

0010046c 4e b9 00 jsr SUB_00300000.l ; Execute subroutine in RAM.

30 00 00

Then later on, this is the subroutine in ROM

which gets copied to RAM and executed:

0010055c 06 97 00

addi.l #0x100000,(SP) ; Adjust the return address on the stack

by $100000 to allow for the ROM moving.

10 00 00

00100562 31 fc 10

move.w

#0x1004,(CSBARBT).w ; Set CSBARBT

(Chip Select Base Address Register Boot ROM) to relocate

05 fa 48 ; the ROM to $100000.

00100568 4e 75 rts ; Return to the

adjusted return address in ROM (at the NEW address).

This ensures that

the CPU is executing code in RAM as the ROM is relocated. This does not require

any cache prefetch tricks.

While the FIRST

method is completely compatible with the boot loader, the second method is

unfortunately not. In order for the boot loader to execute correctly, it also

needs to remount the ROM chip when it starts up. The registers used to control

the ROM base address can only be written to ONCE after the CPU resets, so it is

critical that the boot loader initialised them exactly as the firmware will

want them, as the firmware will be unable to relocate the ROM again when it

starts. So, by the time this firmware startup code executes under the boot

loader, the ROM is already located at $100000 instead of $000000. But the

subroutine executed in RAM makes the assumption that the ROM base address will

change by exactly $100000 and adds this offset to the return address on the

stack. This will not work if the ROM does not in fact move.

In reality, under

the boot loader, this whole piece of code is not required and so the RAM

subroutine call is patched out.

- Firmware

Vector Table – The

firmware vector table is moved from address $100000 to $11E400 in order to

allow the boot loader vector table to be placed at $100000.

- Vector

Base Register Assignment –

Immediately after the code shown above, the firmware startup code sets the

Vector Base Register (VBR) to point to the NEW vector table address

$100000. Under the boot loader, this is no longer correct as the firmware

vector table is relocated to $11E400. The VBR assignment is therefore

patched with the correct vector table address $11E400.

- Local

Identifier Definition Table / Boot Loader ID Definition – The ECU reports its Boot Loader ID over

ISO14230 / KWP2000 service $21 “Read Data by Local Identifier”, record

$33, byte index 8. In order to force the ECU to report the correct new

boot loader ID when running the firmware, the table of record definitions

witing the firmware is located and the definition of Boot Loader ID field

is patched to point to a field containing the new boot loader identifier.

- Diagnostic

Session Control Handler – Natively,

the EU2 ECU supports only the General diagnostic session for ISO14230 /

KWP2000 service $10 “Start Diagnostic Session”. There is no native support

for the Programming diagnostic session, as programming in general is not

supported by the EU2 ECUs. On MEMS3 ECUs, a request to start a Programming

diagnostic session effectively exits the firmware back into the boot

loader. The service handler in the EU2 firmware is therefore patched to

insert code which tests for a request for a Programming diagnostic

session. When detected, it actually executes an ECU reset after placing

some “magic numbers” in particular RAM locations. These numbers survive

the reset and the boot loader code recognises them and does not launch the

firmware. Instead, it continues to execute the boot loader. Before

entering the boot loader main loop, it sends a positive response message

to the original request for the Programming diagnostic session. From the

PC application’s perspective, it simply it simply sends a request for a

Programming diagnostic session and gets the expected response. It is

completely oblivious to the fact that the ECU rebooted between the request

message and the response and communication then proceeds normally from

that point onwards; only the PC application is now talking to the boot

loader, not the firmware.

- Engine

Speed Variable – Putting the ECU into a Programming

diagnostic session whilst driving would be a very bad idea! All engine

management operations would terminate immediately. The patch process

therefore locates the address of the Engine Speed variable in the native

firmware and writes this as metadata at a fixed unused address in the

firmware vector table area. The diagnostic session request handler

described above then uses this to query the engine speed and will only

allow a Programming session to start when the engine is stopped.