Recovering a Bricked Rover MEMS3 ECU Ė Without

Opening the Case

Download

Link: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

NOTE: THIS DOCUMENTATION IS UP TO DATE AS OF VERSION 4.90 RELEASE OF

THE MEMS3 TOOLS APPLICATION SUITE.

In the latest releases of my MEMS Mapper tool I have gone to

great lengths to try to ensure that ECUs cannot be accidentally bricked by

writing bad firmware or map to the ECU. However, there are some things that I

just cannot protect against, for example the user manually editing the memory

bytes in the hexadecimal editor to produce something that is not valid, or

writing a firmware to hardware that just cannot support it. The small but

non-zero risk of bricking an ECU has always bothered me. Whilst researching

these ECUs Iíve bricked many, and the only way to recover them so far has been

to open them up, de-solder the main EEPROM chip using hot air, reprogram the

EEPROM with valid firmware and map using an EEPROM programmer on the bench and

then solder the chip back in, which is tedious and time-consuming problem and

not exactly good for the board and other components.

I always suspected that the engineers who designed it would have

left a back door in somewhere to allow a bricked ECU to be recovered.

Bricked

ECUs

In addition to the firmware and map, the EEPROM chip contains a

boot loader program. When a brand new virgin ECU is suppled, the boot loader is

all that is present. The boot loader has sufficient functionality to allow the

ECU to communicate with a programmer and load the firmware and map. The boot

loader generally checks to see whether valid firmware and map are present and

if so, shortly after the ECU boots it transfers control straight to the

firmware. The boot loader initialises watchdog timers which reboot the ECU if

the firmware appears to have hung up, and what generally seems to happen in the

case of a bricked ECU is that the boot loader sets up the watchdogs, transfers

control to the firmware which fails to operate normally, the watchdogs detect

this and reboots the ECU which then just repeats the same cycle. The ECU is

stuck in an indefinite boot loop. You usually see the fuel pump starting to

prime then being switched off again several times a second forever. Because the

ECU is constantly rebooting, you never get the chance to establish stable

communications with it so cannot even begin to reprogram it with valid firmware

and map.

The boot loader code is protected and permanent. It is loaded into

the first sector of the EEPROM chip at manufacture and the ECU does not appear

to provide any method to erase or modify it. Certainly my MEMS Mapper and

Flasher tools never touch the boot loader in an ECU. This means that whatever

we do to the firmware and map, however badly we screw those up to brick the

ECU, the boot loader will still be clean and valid and just the way it was the

day the ECU was manufactured.

If only I could find some way to prevent the boot loader from

transferring control to the firmware, as though no firmware had been loaded Ö

Back Door

Search

I decided to search for a possible back door by working through a

disassembly of the boot loader code. Now Iíve spent quite a long time looking

at disassembled code from the ECU in the past and I have to say itís not been

anywhere near as successful as I would have hoped. The code is very opaque and

difficult to get into. But I thought that if I was searching for the answer to

a very specific question I might stand a chance, and in this case I had few

pointers to help me get started. For example, once the boot loader jumps into

the firmware, the firmware mostly executes as a separate stand-alone program.

The boot loader should be independent of the firmware, so there are very few

references to firmware addresses in the boot loader code and any references

that I did find were likely to be related to the process of checking for loaded

firmware and launching the firmware.

Back Door

Analysis

The analysis below is based on a disassembly of the VVC 160 ECU

NNN000160ís boot loader ďbootp033Ē but the code varies very little across

different boot loaders.

Subroutine $001007CA is

responsible for jumping into the firmware (at addresses $001007D8, $001007DE and

$001007E2). It loads the address of

the firmware $110000 into register a0, offsets that by 4 bytes and reads the

vector at that address to put the firmware entry point into register a0, then

jumps to the address that register a0 points to:

ROM:001007CA

ROM:001007CA ; =============== S U B R O U T I N E

=======================================

ROM:001007CA

ROM:001007CA

ROM:001007CA sub_1007CA:†††††††††††††††††††††††††††† ; CODE XREF:

ROM:00100622↑p

ROM:001007CA†††††††††††††††† btst††† #0,d1

ROM:001007CE†††††††††††††††† bne.s†† loc_1007E6

ROM:001007D0†††††††††††††††† cmpi.l† #0,d0

ROM:001007D6††††††††† †††††††bne.s††

loc_1007E6

ROM:001007D8†††††††††††††††† movea.l

#dword_110000,a0

ROM:001007DE†††††††††††††††† movea.l

4(a0),a0

ROM:001007E2†††††††††††††††† jmp†††† (a0)

ROM:001007E4 ;

---------------------------------------------------------------------------

ROM:001007E4†††††††††††††††† bra.s†† locret_1007EA

ROM:001007E6 ;

---------------------------------------------------------------------------

ROM:001007E6

ROM:001007E6 loc_1007E6:†††††††††††††††††††††††††††† ; CODE XREF:

sub_1007CA+4↑j

ROM:001007E6†††† ††††††††††††††††††††††††††††††††††††;

sub_1007CA+C↑j

ROM:001007E6†††††††††††††††† bsr.w†† sub_1007F8

ROM:001007EA ;

---------------------------------------------------------------------------

ROM:001007EA

ROM:001007EA locret_1007EA:††††††††††††††††††††††† ††; CODE XREF: sub_1007CA+1A↑j

ROM:001007EA†††††††††††††††† rts

ROM:001007EA ; End of function sub_1007CA

ROM:001007EA

Before executing the firmware, it performs a couple of tests.

Specifically it tests that both bit 0 of register d1 is 0 (at addresses $001007CA and $001007CE) and register d0 contains 0 ($001007D0 and $001007D6)

when the subroutine is called. The firmware is only executed if both of these

tests are passed.

Subroutine $001007CA

above is called right at the end of the main entry point routine of the boot

loader. Before calling $001007CA

this calls other boot loader subroutines $00100628,

$00100708, $00100740 and $001007A2:

ROM:00100612

ROM:00100612 loc_100612:†††††††††††††††††††††††††††† ; CODE XREF:

ROM:00100576↑j

ROM:00100612†††††††††††††† ††bsr.w††

sub_100628

ROM:00100616†††††††††††††††† bsr.w†† sub_100708

ROM:0010061A†††††††††††††††† bsr.w†† sub_100740

ROM:0010061E†††††††††††††††† bsr.w†† sub_1007A2

ROM:00100622†††††††††††††††† bsr.w†† sub_1007CA

ROM:00100626

ROM:00100626 locret_100626:†† †††††††††††††††††††††††; CODE XREF:

ROM:00100610↑j

ROM:00100626†††††††††††††††† rts

ROM:00100628

Subroutine $00100740

checks for the $5AA5 signatures of the firmware (at firmware address $110410, in code starting at address $00100752) and map (at map address $13C012, in code starting at address $0010075E) (you can look at these

addresses in any valid firmware and map using MEMS Mapper and see that they do

indeed always contain the signature bytes $5AA5) and sets bits in register d0

if they are not found, so the check for register d0 being 0 amounts to a check

that firmware and map are loaded.

ROM:00100740

ROM:00100740 ; =============== S U B R O U T I N E

=======================================

ROM:00100740

ROM:00100740

ROM:00100740 sub_100740:††††††††† †††††††††††††††††††; CODE XREF: ROM:0010061A↑p

ROM:00100740†††††††††††††††† movea.l

#dword_110000,a0

ROM:00100746†††††††††††††††† clr.l†† d0

ROM:00100748†††††††††††††††† cmpi.w† #0,d7

ROM:0010074C†††††††††††††††† bne.s†† loc_100752

ROM:0010074E††††††††††† †††††bset†††

#1,d0

ROM:00100752

ROM:00100752 loc_100752:†††††††††††††††††††††††††††† ; CODE XREF:

sub_100740+C↑j

ROM:00100752†††††††††††††††† cmpi.w† #$5AA5,$410(a0)

ROM:00100758†††††††††††††††† beq.s†† loc_10075E

ROM:0010075A†††††††††††††††† bset††† #0,d0

ROM:0010075E

ROM:0010075E loc_10075E:†††††††††††††††††††††††††††† ; CODE XREF:

sub_100740+18↑j

ROM:0010075E†††††††††††††††† movea.l

#word_13C000,a0

ROM:00100764†††††††††††††††† cmpi.w† #$5AA5,$12(a0)

ROM:0010076A†††††††††††††††† beq.s†† loc_100770

ROM:0010076C†††††††††††††††† bset††† #2,d0

ROM:00100770

ROM:00100770 loc_100770:†††††††††††††††††††††††††††† ; CODE XREF:

sub_100740+2A↑j

ROM:00100770†††††††††††††††† movea.l

#unk_110400,a1

ROM:00100776†††††††††††††††† movea.l

#word_13C00A,a0

ROM:0010077C††††††† †††††††††move.b†

#0,d2

ROM:00100780†††††††††††††††† bra.s†† loc_100786

ROM:00100782 ;

---------------------------------------------------------------------------

ROM:00100782

ROM:00100782 loc_100782:†††††††††††††††††††††††††††† ; CODE XREF:

sub_100740+5E↓j

ROM:00100782†††††††††††††††† addi.b† #1,d2

ROM:00100786

ROM:00100786 loc_100786:†††††††††††††††††††††††††††† ; CODE XREF:

sub_100740+40↑j

ROM:00100786†††††††††††††††† cmpi.b† #7,d2

ROM:0010078A†††††††††††††††† bgt.s†† locret_1007A0

ROM:0010078C†††††††††† ††††††move.b†

(a1),d1

ROM:0010078E†††††††††††††††† cmp.b†† (a0),d1

ROM:00100790†††††††††††††††† beq.s†† loc_100796

ROM:00100792†††††††††††††††† bset††† #3,d0

ROM:00100796

ROM:00100796 loc_100796:†††††††††††††††††††††††††††† ; CODE XREF:

sub_100740+50↑j

ROM:00100796†††††††††††††††† adda.w† #1,a0

ROM:0010079A†††††††††††††††† adda.w† #2,a1

ROM:0010079E†††††††††††††††† bra.s†† loc_100782

ROM:001007A0 ;

---------------------------------------------------------------------------

ROM:001007A0

ROM:001007A0 locret_1007A0:††††††††††††††††††††††††† ; CODE XREF:

sub_100740+4A↑j

ROM:001007A0†††††††††††††††† rts

ROM:001007A0 ; End of function sub_100740

ROM:001007A0

ROM:001007A2

So we now know that the firmware will be executed if both firmware

and map are loaded and bit 0 of register d1 is 0 when subroutine $001007CA is called. We also know from

previous experience that when an ECU does not have firmware or map loaded, it

happily runs the boot loader and allows normal programming over OBDII using the

MEMSMapper application. Looking at the code, I would expect identical

behaviour if the other test failed, i.e. if bit 0 of register d1 is 1 when

subroutine $001007CA is called. So

if we can find a way of setting this bit at this point, we should have a way of

preventing the ECU from executing the firmware and accepting programming just

as though it was a virgin ECU, and that would be the

back door we were looking for.

So what is bit of 0 of register d1 doing?

Subroutine $001007A2,

which is called in the boot loader immediately before the signature checking

routine $00100740 above, manipulates

bit 0 of d1, and so it determining the other requirement for the firmware to be

executed. Itís a very simple subroutine which sets bit 0 of d1 entirely based

on registers of the QSM (Queued Serial Module) in the MC68336 microcontroller:

ROM:001007A2

ROM:001007A2 ; =============== S U B R O U T I N E

=======================================

ROM:001007A2

ROM:001007A2

ROM:001007A2 sub_1007A2:†††††††††††††††††††††††††††† ; CODE XREF:

ROM:0010061E↑p

ROM:001007A2†††††††††††††††† btst††† #6,($FFFFFC0D).w

ROM:001007A8†††††††††††††††† beq.s†† loc_1007C4

ROM:001007AA†††††††††††††††† cmpi.b† #$96,($FFFFFC0F).w

ROM:001007B0†††††††††††††††† bne.s†† loc_1007C4

ROM:001007B2†††††††††††† ††††bset†††

#0,d1

ROM:001007B6†††††††††††††††† bset††† #0,($FFFFFC0B).w

ROM:001007BC†††††††††††††††† bclr††† #0,($FFFFFC0B).w

ROM:001007C2†††††††††††††††† bra.s†† locret_1007C8

ROM:001007C4 ; ---------------------------------------------------------------------------

ROM:001007C4

ROM:001007C4 loc_1007C4:†††††††††††††††††††††††††††† ; CODE XREF:

sub_1007A2+6↑j

ROM:001007C4†††††††††††††††††††††††††††††††††††††††† ;

sub_1007A2+E↑j

ROM:001007C4†††††††††††††††† bclr††† #0,d1

ROM:001007C8

ROM:001007C8 locret_1007C8:††††††††††††††††††††††††† ; CODE XREF:

sub_1007A2+20↑j

ROM:001007C8†††††††††††††††† rts

ROM:001007C8 ; End of function sub_1007A2

ROM:001007C8

ROM:001007CA

If bit 6 of QSM register SCSR is 0 (tested at addresses $001007A2 and $001007A8) then bit 0 of register d1 is cleared to 0 (at address $001007C4), otherwise if the low byte

of QSM register SCDR is not $96 (tested at addresses $001007AA and $001007B0)

then bit 0 of register d1 is also cleared to 0 (at address $001007C4), otherwise bit 0 of d1 is set to 1 (at address $001007B2), bit 0 of QSM register SCCR1

is toggled to 1 then 0. The subroutine then exits in all cases.

Now the SCSR register is the SCI Status Register and SCDR register

is the SCI Data Register, and the SCI is the Serial Communications Interface

which is part of the QSM. It is basically a standard UART serial port. SCSR

tells us about the current status of port operation and SCDR holds the most

recent byte received. From the MC68336 data sheet, Bit 6 of the status register

SCSR is the RDRF flag, or Receive Data Register Full Ė it tells us if thereís

something in the data register SCDR.

So the condition which determines that a loaded firmware should be

executed is simply that no byte has been received by the SCI port, or that byte

was not $96.

In other words, we can prevent any loaded firmware being executed

by sending the byte $96 to the SCI port at the right moment.

That leaves three questions:

1)

What is the right moment?

2)

What is the SCI port connected to?

3)

What Baud rate should we transmit the $96 at?

The answer to question 1 is clearly ďas the ECU bootsĒ, but

exactly when during the boot sequence is not easy to determine, so I decided to

try the approach of just broadcasting the byte $96 continuously as the ECU was

powered on. I couldnít be sure this would work but it was certainly worth a

try.

The answer to question 2 seemed likely to be the OBDII serial

port. My guess was that SCI was just connected to the OBDII K-Line as this was

used for serial UART communications with the ECU. It would be extremely

convenient if this turned out to be the case as I could provide a utility

within MEMS Mapper that just broadcast $96 to the OBDII port while you powered

the ECU on.† Again, I couldnít be sure

this was the case without a lot more digging in the firmware disassembly or

tracing the electronics, but the easiest thing was to give it a try.

As for question 3, one of the subroutines called immediately prior

to those discussed above by the boot loader was $00100628, and that contained the following lines:

ROM:0010069E

ROM:001006A0 ;

---------------------------------------------------------------------------

ROM:001006A0

ROM:001006A0 loc_1006A0:†††††††††††††††††††††††††††† ; CODE XREF:

ROM:0010051A↑j

ROM:001006A0†††††† ††††††††††move.w† #$34,($FFFFFC08).w ; '4'

ROM:001006A6†††††††††††††††† move.w† #$C,($FFFFFC0A).w

ROM:001006AC†††††††††††††††† bra.l†† loc_100520

ROM:001006B2 ;

---------------------------------------------------------------------------

ROM:001006B2

These load the SCCR0 register of the QSM with the value $34 (at

address $001006A0). SCCR0 is the SCI

Control Register 0 and controls the Baud rate at which the SCI port operates,

according to the formula Baud Rate = (Clock Frequency) / 32 / SCCR0. So with a

system clock frequency of 16Mhz and an SCCR0 value of $34 or 52 decimal, the

Baud rate was configured to 16000000 / 32 / 52 = 9615, which is as close as you

can get to the standard OBDII Baud rate of 9600 Baud. This provided even more

evidence that I was on the right lines thinking that the SCI port was actually

the OBDII K-Line.

So my plan was to broadcast $96 at 9600 Baud over the OBDII port

while booting up the ECU and Ö rather to my surprise, it worked! Thatís the back door I was looking for.

So that

provides a failsafe way of being able to recover a bricked ECU. Iíve

tested using it to prevent a perfectly healthy ECU from executing the firmware

- the ECU just sits in boot / programming / recovery mode in the boot loader

waiting to be programmed. Iíve tested communications with the ECU after

blocking the firmware with this signal and all seems normal. Finally Iíve used

to unbrick a development ECU that got bricked while I was playing with it. Iím

pretty much 100% sure that this method will unbrick any MEMS3 ECU that has bad

firmware or map as the boot loader code is protected and always virgin. It

doesnít matter how the ECU was bricked, whether it was using MEM3 Flasher /

Mapper or other programming tools such as Galletto, this method provides a safe

recovery option.

Recover

Bricked ECU

In release 4.87 of MEMS Flasher and MEMS Mapper Iíve now added

an option to the ECU Tools menu to Recover Bricked ECU. When you select

this option, the application will begin to broadcast the request code at

regular intervals and monitor for the expected response. If the ECU is stuck in

a boot loop, constantly rebooting, it should recover almost immediately as the

next time it reboots it will detect the request and remain in the boot loader

ready to accept programming. If the response is not detected within a short

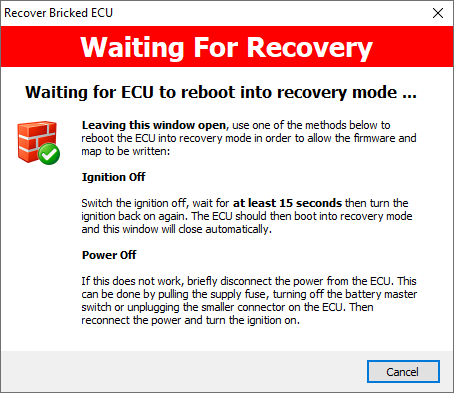

time, the following dialog is displayed:

If the ECU is hanging and unable to communicate, we need to

persuade it to reboot. Switching the ignition off for at last 15 seconds (and

then back on again) is usually sufficient to ensure that it will perform a full

boot when powering on again. At this point it should again remain in the boot

loader ready to accept programming as above. If the ECU was really tightly

stuck in a loop, then just occasionally switching the ignition off is not

sufficient to break it out of the loop and trigger a reboot. In this case, you

need to briefly remove power from the ECU. When power is re-applied and the

ignition is turned on it will boot again, detect the request and remain in the

boot loader ready to accept programming as above.

Depending on the timing of the request code, it may occasionally

require more than one attempt to recover an ECU.

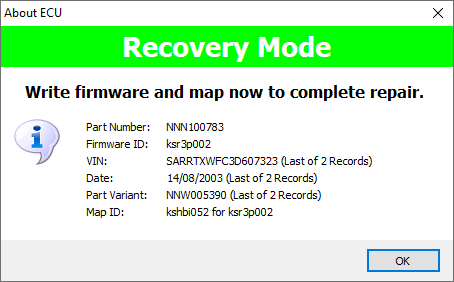

When the expected response is detected, the following dialog is

displayed:

Once the ECU has recovered into a state where it is running the

boot loader and willing to communicate with the application again it is

important that you then write a good replacement firmware, map or both

(depending on what was damaged, if in doubt do both). The initial recovery is

only temporary; we have broken the ECU out of the cycle that was preventing it

from communicating and accepting programming using the special code, but next

time it reboots without seeing the request broadcast it will of course continue

to try to execute the damaged firmware or map as before. In recovery mode, some

of the ECU tools and operations will fail (the ECU will reject the operations

as it will not be running the firmware) and it will not provide any engine

management functionality, but everything necessary to read and write the

firmware and map will function normally.

Once you have rewritten the ECU the repair will be permanent.