MEMS3 Firmware Immobiliser Delete –

Including Rover 75 / MG ZT / Freelander BMW EWS 3.D

Download

Link: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

Using my MEMS Mapper you can now

easily delete the immobiliser functionality, even with the BMW EWS 3.D secure immobiliser

system.

This is something that quite a few people

have asked me for. For ECUs that are set up to use the Lucas 5AS or Pektron

immobiliser systems, there is a scalar in the map which allows the ECU to run

without needing a coded signal from an immobiliser. For ECUs that are set up to

use the BMW EWS 3.D immobiliser system, this does not work. These ECUs are

found in some Rover 75, MG ZT and Land Rover Freelander models. Once the ECU

has been paired with one BME EWS immobiliser, it cannot be paired with another.

This makes it very difficult to replace ECUs, either in case of failure or when

doing turbo conversions and engine swaps etc. People have been asking me if it

was possible to replace the BMW EWS functionality in the ECU with the equivalent

Lucas 5AS routines (too complicated at the moment!) or alternatively to delete

the immobiliser functionality altogether, leaving the ECU set to “free run”.

By following the instruction below, you

will be able disable the immobiliser functionality in any MEMS3 ECU with any

immobiliser system.

Basic Instructions

You will need to download the latest

version (5.54 or later) of my MEMS Tools from here: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

Using this version, perform a full read

(both Firmware & Map) from the

ECU.

Finding the immobiliser code which needs

to be modified is a little bit complicated, so I’ve added a wizard to do it for

you.

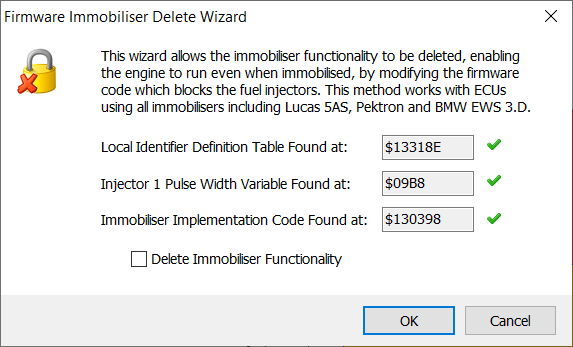

Click Tools, Wizards, Firmware

Immobiliser Delete and you should see a dialog like this:

If there are three green tick marks

shown, the wizard has been able to trace the immobiliser code (it finds them

correctly in every unmodified firmware that I’ve ever seen).

Check Delete Immobiliser Functionality and then click OK.

This deletes the immobiliser

functionality in the current project in MEMS Mapper – you now need to write

the Firmware & Map back to the ECU in the normal way.

Technical Details

All of the ECUs fuelling calculations end

up with one single number – the injector pulse width. This is the time for

which the injector needs to be open in order to inject an appropriate quantity

of fuel. One of the very last things the ECU does is to check a number of flags

which control engine immobilisation under different conditions (some of which

were related to factory development mode code). If any of these flags result in

immobilisation being disabled, it skips over the critical instruction,

otherwise it overwrites the calculated injector pulse width with 0, meaning

that the injector is open for zero time (doesn’t open at all). You can see the

various tests being done here in green in a ksr3p004, NNN000160 VVC 160 ECU. The instruction that

effectively immobilises the engine is shown in yellow.

LAB_00130382

00130382 08 38

00 btst.b 0x7

,(BYTE_0000131f ).w

07 13 1f

00130388 66 08

bne.b LAB_00130392

0013038a 08 38

00 btst.b 0x7

,(varBitFlags1323 ).w

07 13 23

00130390 67 14

beq.b LAB_001303a6

LAB_00130392

00130392 08 38

00 btst.b 0x7

,(BYTE_0000131a ).w

07 13 1a

00130398 66 0c

bne.b LAB_001303a6

0013039a 21 bc

00 move.l

#0x0 ,(BYTE_000009b8 ,-,D0w *0x4 )

00 00 00

05

a0 09 b8

001303a4 60 06

bra.b LAB_001303ac

LAB_001303a6

The instruction show in blue is the last chance to

skip over the instruction. It’s a “conditional branch” instruction “bne” which

means “jump forward by a set number of instructions if the bit tested in the

last test was 1”.

Engine immobilisation can be disabled

simply by changing this one instruction from a “conditional branch” instruction

“bne” (branch if not equal) to an “unconditional branch” instruction “bra”

(branch always). This means changing a single byte from $66 to $60 and means

that the immobilisation instruction is always skipped, irrespective of the

immobilisation flags.

The complicated part is finding this

particular instruction, as it will be at a different memory address in every

different MEMS3 firmware version (of which there were hundreds), and there will

be many very similar instructions throughout the firmware. The good news is

that the code was highly conserved right across the MEMS3 product line and

therefore we know what we are looking for and know what to do with it when we

find it.

In my article on TestBook T4 (Main Dealer) Level Support for MEMS3

I described how I was using Service $21 "Request Data By Local ID" to

request live data from the ECU. Inside the firmware there is a table of

definitions, listing the fields (mostly RAM variable addresses) for the

response record for each local identifier. My code searches for this table by

scanning the whole firmware for instructions of the form LEA (NNNNNN).L,AN.

Whenever it finds one, it examines the address loaded to see if it looks like

it points to the table. It puts some pretty tough conditions on what can and

cannot be considered to be the table so it should get it right every time. It

tries to walk the whole table from start to end and only accepts it if it finds

plausible records all the way through, the expected $FFFF “end of table marker”

at the end, no duplicate identifiers and all of the mandatory record

identifiers expected.

Once it’s found that, it extracts the

Injector 1 Pulse Width variable address from the record definition for

identifier $0C and then scans the firmware for a conditional branch followed

immediately by the instruction that zeroes that out, as shown above.