MEMS3 Flywheel Trigger Pattern

Changes

Download

Link: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

Using my MEMS Mapper you can now

easily adjust the map to work with a different flywheel trigger pattern.

This follows on from the work I did on

allowing a MEMS3 from a Rover 75 or MG ZT to run without its matched BMW EWS

immobiliser. The driver behind this was to allow an MG ZT-T engine and ECU to

be transplanted into say an MG ZR. Having solved the immobilisation issue, it

was then pointed out to me that the MG ZT uses a completely different flywheel

and gearbox to other K Series installations and the flywheel trigger pattern

was also different, so a ZT ECU would not run with a ZR flywheel. So I set

about hunting for the code that managed the flywheel tracking, wondering if I

would be able to figure out how to change the pattern. To be honest I was

expecting this to be a hard one, and I read up on the

TPU (Time Processing Unit in the MC68336 microcontroller) ready for a fight …

but once I started to dig into it, the answer was actually quite simple, as

I’ll describe later in this article. In the meantime …

By following the instruction below, you

will be able to tell the MEMS3 ECU about the new flywheel trigger pattern so

that it will then synchronise correctly.

This may be of direct use on a Caterham

when upgrading an early MEMS 1.9 engine to MEMS3 without swapping the flywheel.

Basic Instructions

You will need to download the latest

version (5.56 or later) of my MEMS Tools from here: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

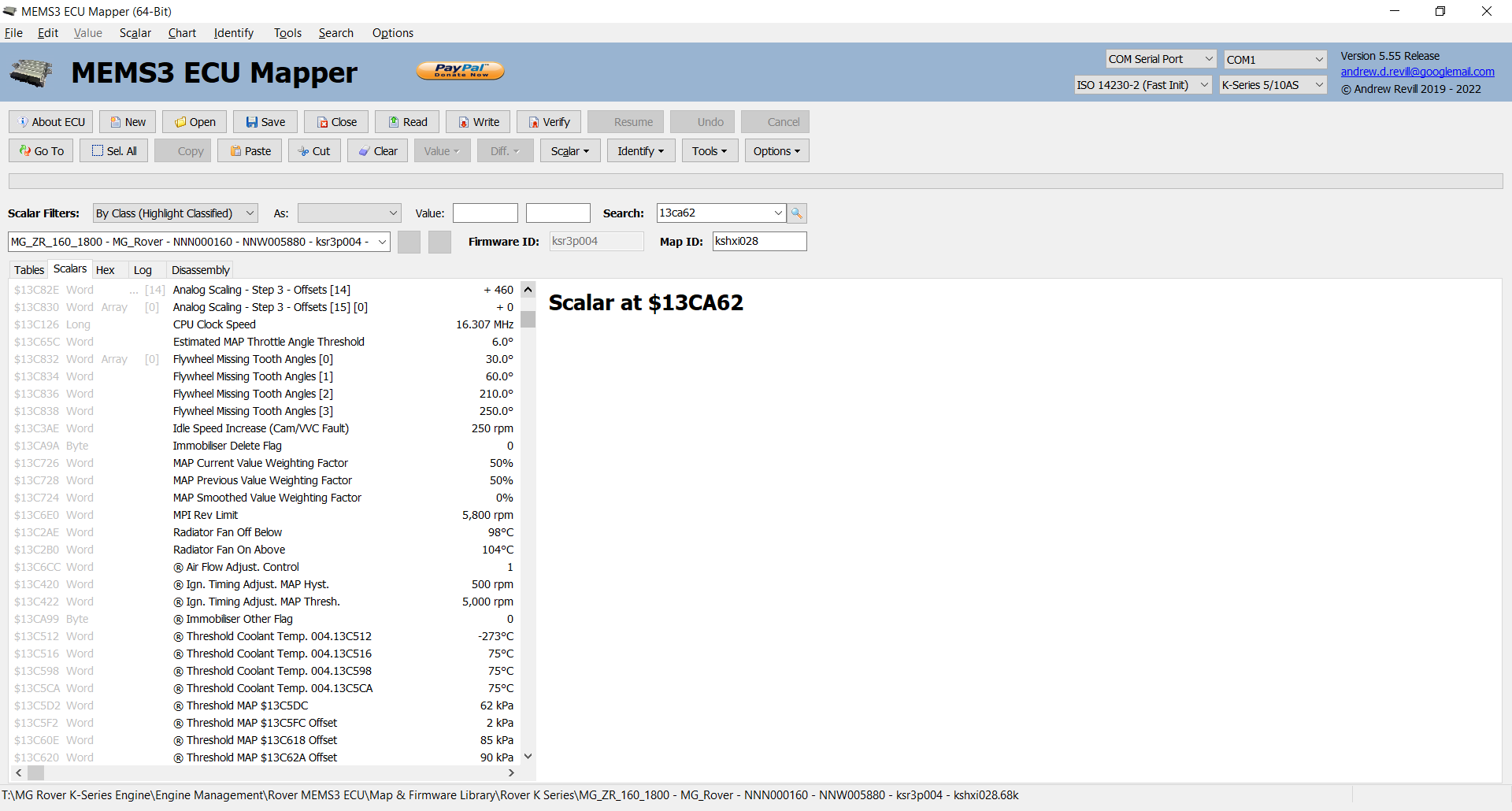

If you open a file or read the map from

an ECU using this version you should see some scalars listed, with descriptions

“Flywheel Missing Tooth Angles[0]” to “Flywheel

Missing Tooth Angles[3]” as shown below.

If you are using a firmware version that

I haven’t seen, these will not be found. In that case just click Identify,

Keep Existing and it should find them all automatically.

All you need to do is enter the new

missing tooth angles, in degrees ATDC in increasing order, into these four

scalars.

Just to make it a little more convenient

to edit and validate them in one place, and to allow you to select from a

number of predefined flywheel patterns, I’ve added a wizard to do it for you.

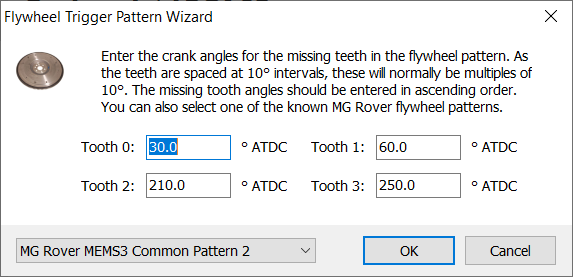

Click Tools, Wizards, Flywheel Trigger

Pattern and you should see a dialog like this:

If this menu

item is disabled, the application has not been able to identify the relevant

scalars in the map. Ensure that you have used the Identify, Keep Existing system to identify the scalars.

In this

dialog you enter the four missing tooth angles, in ascending order. You can

also just select one of the standard flywheels from the combo box to populate

the dialog with the correct numbers. Standard flywheels provided include the MG

Rover MEMS 1.9 Common Pattern (0°, 120°, 180°, 310°), MG Rover MEMS 2J/3 Common

Pattern (30°, 60°, 210°, 250°) and Rover 75 or MG ZT Specific Pattern (80°,

120°, 270°, 300°). As the patterns are all based on 36 teeth, the teeth are

always spaced at 10° intervals and the tooth angles are normally integer

multiples of 10°.

If you are

using a different flywheel and you have some numbers, please let me know and

I’ll add it to the list.

When you’re done, click OK to

update the current map. If the OK button is disabled it means that the

angles entered are invalid, for example duplicated or out of order.

This wizard is compatible with live

mapping mode and will let you play with the flywheel trigger pattern on a live

engine.

Technical Details

I original expected this to be a hard one

to find.

Inside the MC68336 microcontroller in the

ECU is a Time Processor Unit (TPU). This turns out to be very flexible and

powerful. It has 16 channels, each of which can be programmed in microcode to

perform a different timing function. Channel 0 is programmed to track the crank

sensor signal and generate interrupts with the passing of the teeth that allow

the CPU to track the flywheel position. Channels 1 & 2 are slaved to

Channel 0 and are programmed to trigger interrupts at given points in the cycle

– driving the ignition coils. Channels 3, 4, 5 & 6 are slaved to Channel 0

and are programmed to trigger interrupts at other points in the cycle – driving

the fuel injectors. Most of the timekeeping of the engine is therefore

performed by the TPU alone without direct intervention of the CPU, whose job it

is to monitor conditions and update the parameter of the TPU.

I went looking for the coding of the flywheel trigger pattern in the TPU management, following examples such as this: Period Measurement With Missing Transition Detection TPU Function (PMM), by Motorola / Freescale / NXP who make the microcontroller. Following the examples, one of the first things I looked at in the ECU code was the routine that handled the TPU interrupt for TPU Channel 0, and that led me to the routine that manages the internal RAM variable for Crankshaft Rotation Position, which starts off like this:

*************************************************************

*

* FUNCTION

*************************************************************

undefined funProcessCrankshaftRotation ()

undefined D0b:1 <RETURN>

undefined2 Stack[-0x2]:2 local_2 XREF[2]: 0011127a (*) ,

00111280

(*)

funProcessCrankshaftRotation XREF[1]: FUN_00110d4a:00110dfa (c)

00111120 70 05 moveq

#0x5 ,D0

00111122 32 35 03

move.w (0x832 ,A5,D0w *0x2 ),D1w

20 08

32

LAB_00111128 XREF[1]: 00111132

(j)

00111128 6c 0a bge.b

LAB_00111134

0011112a 53 40 subq.w #0x1 ,D0w

0011112c 32 35 03

move.w (0x832 ,A5,D0w *0x2 ),D1w

20 08

32

00111132 60 f4 bra.b LAB_00111128

LAB_00111134 XREF[1]: 00111128

(j)

00111134 42 47 clr.w D7w

00111136 34 38 04

c6 move.w (varWordCrankshaftRotationalPosition_S21

).w,D2w

0011113a 04 42 00

64 subi.w #0x64 ,D2w

0011113e 3a 3c 0e

10 move.w #0xe10 ,D5w

00111142 da 6d 08

32 add.w (0x832 ,A5),D5w

00111146 32 35 03

move.w (0x832 ,A5,D0w *0x2 ),D1w

20 08

32

…

Straight away I noticed the bits I’ve

highlighted in the above listing. The whole routine is heavily dependent on an

array of scalars at offset 0x832 in the map. And I went to look what was in

that array, there were the four missing tooth angles.

And it turns out the routine isn’t really dependent on anything else, those four tooth angles are all it needs and uses to

track the crank angle.

I don’t have access to a Rover 75 or MG

ZT to test this on, so I had to test it on an ECU test harness.

My test harness generates crank and cam

sensor signals corresponding to MG Rover MEMS 2J/3 Common Pattern (30°, 60°,

210°, 250°). When I flashed a Rover 75 firmware and map onto a test ECU, it

would not synchronise with my test harness at all. The ignition coils and

injectors were firing away but in an erratic pattern, and live diagnostics

showed that the ECU thought it was cranking rather than running; it was

recognising that there was a signal from the crank sensor, but it was unable to

synchronise to it.

When I used the above method to change

the flywheel pattern in the Rover 75 map and flashed it onto the test ECU

again, it synchronised and appeared to be running normally. The ignition was

firing in a regular pattern and the injectors were firing sequentially. But to

be sure, I had to confirm that the engine timings were as expected. To do this,

I took a VVC firmware and map and a Rover 75 firmware and map. In the maps I

took out all of the adjustments applied to the ignition timing and modified the

ignition timing table to hold a constant value at all MAP and RPM values. This

meant that I knew exactly what the ignition timing should be on my test

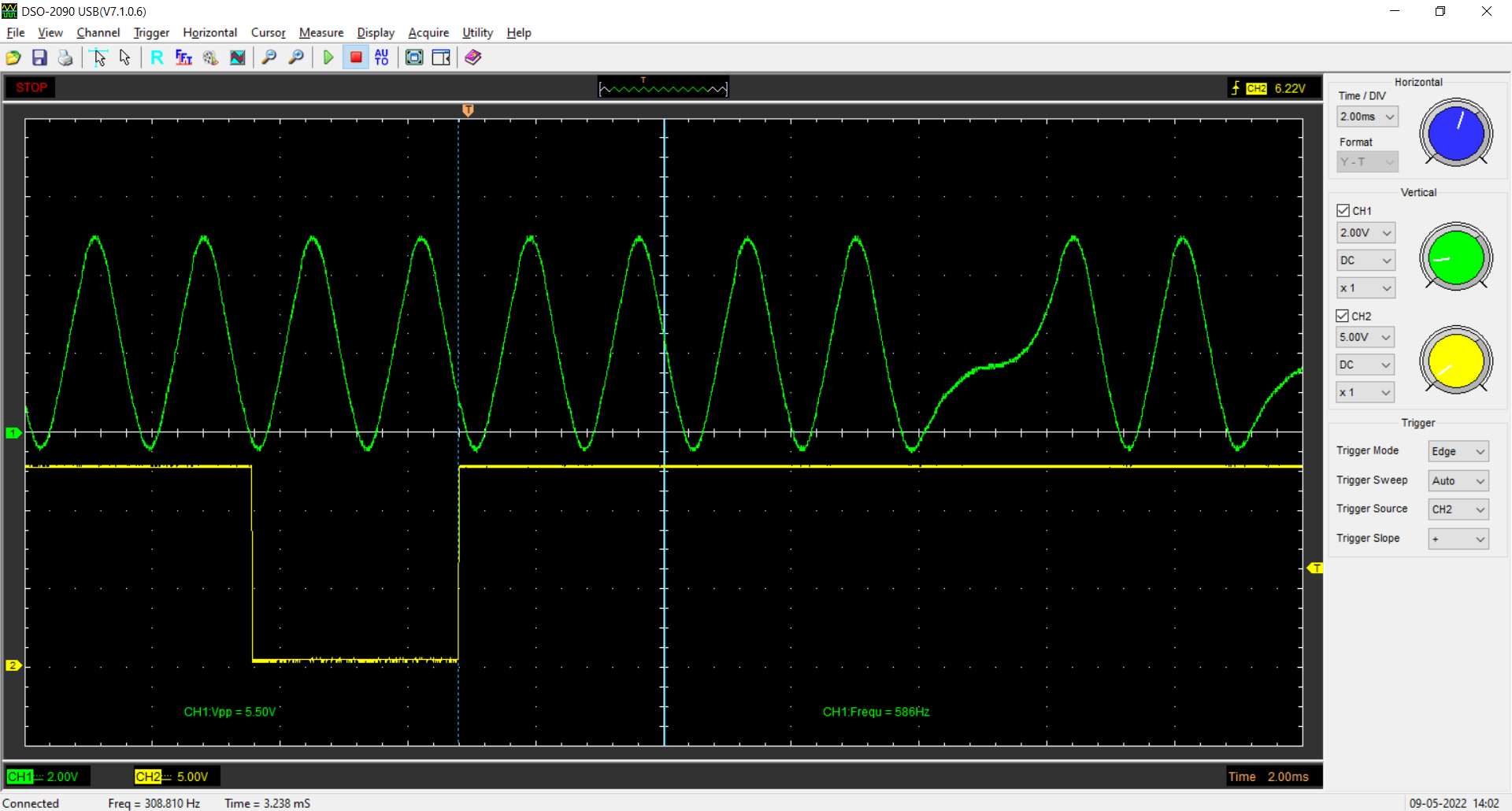

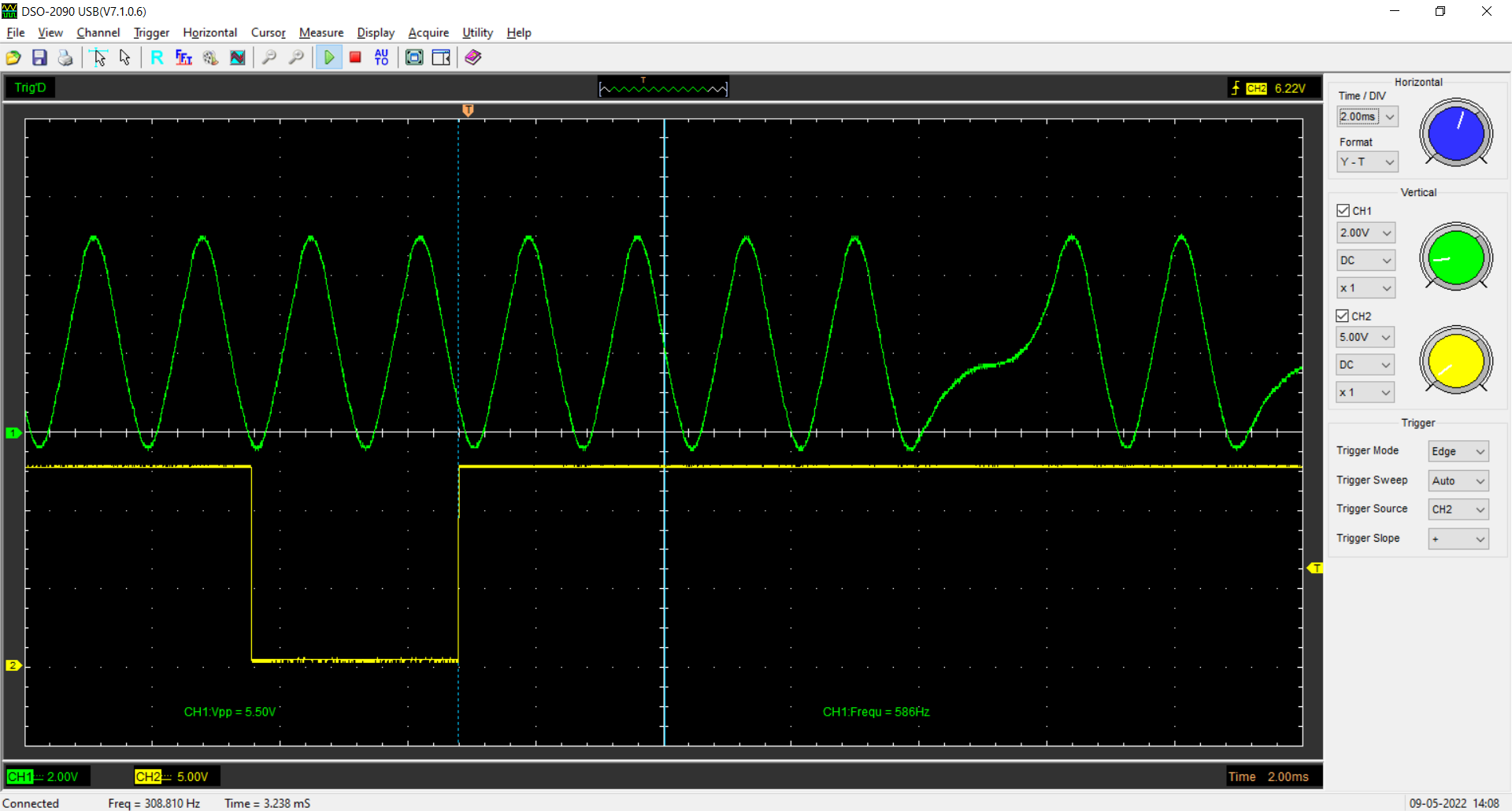

harness. I was then able to attach an oscilloscope to the crank signal and the

ignition coil drive.

Stock VVC Map:

Flywheel-Swapped Rover 75 Map:

These are arranged such that the heavy

vertical scale line in the middle is at TDC. The closely-spaced peaks in the

crankshaft signal are at 10° intervals, so the point at which the ignition coil

fires (the rising edge of the yellow line) is at approximately 20° BTDC, which

is the value I had programmed into the tables. You can see that the

flywheel-swapped Rover 75 map is a very close match indeed for the VVC map, and

so the ECU with the Rover 75 map is now correctly tracking the flywheel

position based on the standard trigger pattern. Similar measurements on the

injector timing also yielded the expected results (after a bit of head scratching;

the very early NNN100683 ECU, which I already knew to be riddled with bugs in

its OBDII code, seems to fire the injectors exactly 10° later than specified in

the map, even with the stock flywheel, but later 75 ECUs behaved as expected).