MEMS3 Firmware Correlation –

Identifying Tables & Scalars in All Firmware Versions

Download

Link: https://andrewrevill.co.uk/Downloads/MEMSTools.zip

MEMS Mapper can now identify known

tables and scalars in almost all firmwares with a very high degree of accuracy.

There are many different firmware

application versions for the MEMS3 ECU, covering numerous iterations of the

MPI, VVC, automatic, turbo, Rover 75 and Freelander flavours of the ECU, as

well as several variants of the Land Rover Td5 ECU. Since I first wrote MEMS3

Mapper, it has had the ability to identify known tables and scalars in

previously unseen firmware versions. This is achieved by comparing the data in

tables with all tables seen previously in other firmwares and looking for

similarities. For large tables mapped in high resolution, such as ignition

timing and fuelling / VE tables, this has generally worked well. However, a lot

of the smaller tables often only contain a few data points, and in some maps

whole features are disabled in which case the corresponding tables may reduced

to a single point with a zero value, which doesn’t provide enough information

for a reliable identification. For scalars, the matching algorithm relied on

spotting similar patterns of numbers either side of the scalar in question.

This has also generally worked quite well, but was not infallible. So, in some

cases, in unkeen firmwares, the application has misidentified tables and

scalars.

Recently I was fortunate enough to be

given copies of a full set of the Rover T4 system CDs. Initially I didn’t think

there was actually a lot I could do with them, not having a T4 system myself,

but then it occurred to me that the T4 system was capable of upgrading any

MEMS3 to the latest (at the time of issue) firmware and map for that particular

vehicle, which must mean that there was a large selection of firmware and map

files somewhere on the CDs, probably covering all of the firmware versions ever

issued to the dealer network, which in all probability meant the vast majority,

if not all, of the firmwares ever installed on production vehicles. So, I went

digging.

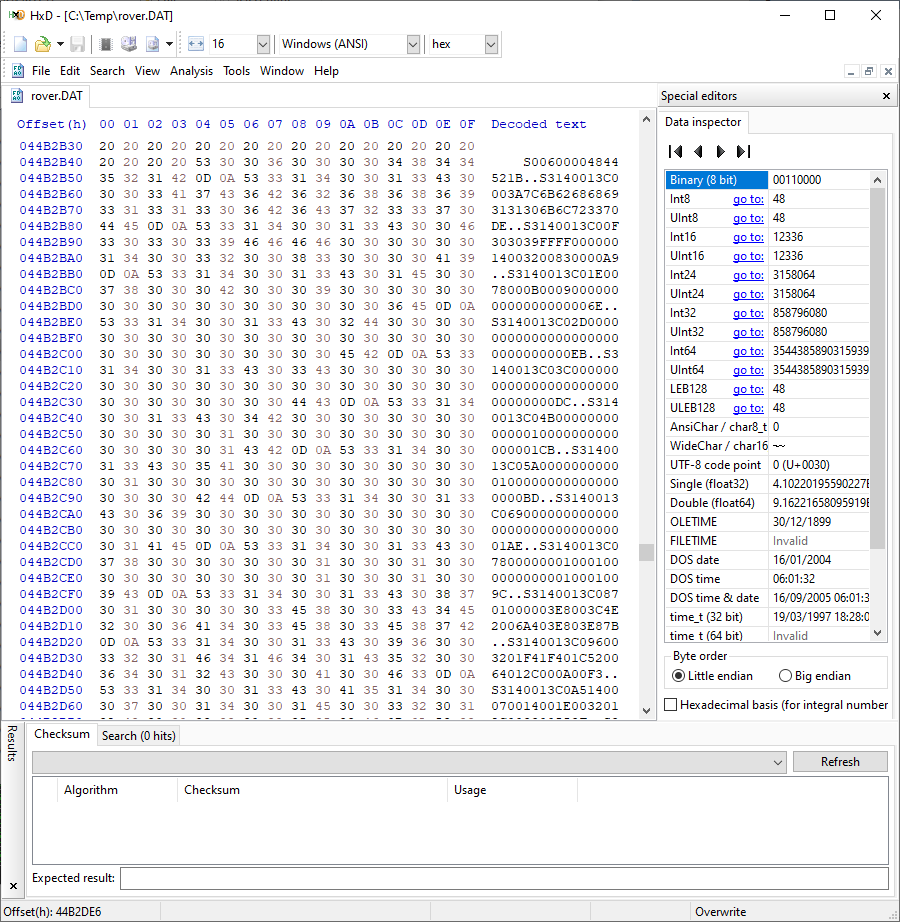

At first there was nothing obvious;

certainly not a nice folder containing firmware and map files that I could

recognise. But on each CD there was a large database

file ROVER.DAT and a corresponding index file ROVER.IDX. Many different

database engines over the years have used .DAT and .IDX file extensions and I

tried to open these files with numerous different drivers for all of the main

suspects, but none of them worked. So I tried doing it

the hard way and opening the database files in a binary editor and searching

for byte sequences which I knew to be in the firmware. Sadly, nothing showed

up. Then I thought, what if they’re actually held as hexadecimal-encoded text

strings in text fields? So tried searching for the hexadecimal representations

of known byte strings, and BINGO! There they were. With a bit more poking, I

realised that they were in Motorola SREC format, which was not at all

surprising as the ECUs were made by Motorola.

Finding all of the maps and firmwares in

SREC format made them really easy to parse out and extract. As I couldn’t read

the databases properly, I had no identification information for each file, but

luckily the firmware and map IDs, and the firmware ID for each map, are encoded

into the headers of the files. I therefore was able to extract a full set of

firmware and a full set of maps, and pair them up based on their IDs to produce

full ECU images. Unfortunately I still wasn’t able to

identify exactly what vehicle each pair was associated with, but there was

still a lot I was able to do with these files. The complete library of all of

the files recovered is online here: MapFirmwareLibrary/From%20TestBook%20T4%20CDs/

with some 166 files in total, covering 40 different petrol firmware versions

and 13 Td5 diesel firmware versions.

Armed with every firmware version ever

issued, I was in a position try to do a much better job of correlating all of

the tables and scalars across all firmware versions, making the problematic

in-application identification algorithm pretty much obsolete.

I ran every single firmware version

through a disassembler to produce a plain-text, assembly language listing (the

MEMS Mapper application already used these files in the same format for

automated reverse-engineering when installing customised firmware patches

etc.).

My first attempt was then to try to

correlate all of the tables by hand. I made some changes to MEMS Mapper to

allow me to:

1.

On any table or

scalar, right click and select “Search Firmware” to see the point(s) in the

assembly language listing where the table or scalar was referenced.

2.

On any table or

scalar, hold the mouse over the table list for a pop-up hint showing the listing

of the code which referenced it.

I then spent many, many evening hours

comparing not only the data in each table, but the code that accessed it,

trying to work out and make a judgement call what corresponded to what. It took

days of effort, but I got there in the end and was convinced that I’d done a

reasonable job. But trying to do it for the scalars filled me with dread. It

was a mammoth task for the tables, where I had a lot more data to go on and

typically 150 tables in any firmware version. There were

something like 1400 unique scalar values to trawl through, and each one was

just a single number. There was no way I was going to be able to do them all by

hand. So I set about trying to write program code to

do what I had done on the tables by hand, i.e. to compare the code accessing

tables and scalars and to identify where it was similar (not necessarily

identical, as the code did change in places over time).

I tried several different comparison

algorithms. Most of them revolved around looking for “similar” instructions at

“similar” distances from the code that accessed particular tables. I tried

weighting the scores based on the distances of the instructions from the table

reference (code further away was considered less relevant) and the distance between

matching instructions in the two firmwares (matches in corresponding positions

were considered more significant). They were all plagued by problems. The main

issue was trying to define what was “similar” in a way that caught all of the

places where tables were accessed by slightly different code, without linking

together unrelated tables just because there were similarities in the code

around them. Without being able to follow the full program flow logic (which

was almost impossible to do in an automated way) I was left with blindly

comparing code in proximity to the table access, and that had a number of

problems:

·

A lot of tables

seemed to be accessed by dedicated subroutines with the structure: Load

register d1 with the table address, load register d2 from the variable that

holds the X-axis value, load register d3 from the variable that holds the

Y-axis value (in the case of a 3D table), call the table lookup function, store

the result d1 into a variable. In other words, the code immediately surrounding

the table access was identical across many tables.

·

This meant I had to

look beyond the subroutine in which they were accessed. But following the tree

of calls was just impossibly complex, so I had to content myself with looking

at the structure of preceding and subsequent subroutines.

·

These could also be

very similar, as you often see a long run of consecutive identical table-getter

routines in the code.

·

I often found code

inserted before or after a table-getter routine between two different

firmwares, which meant the code after the getter might be identical, whereas

the code before it was unrelated. So I had to resort

to scoring the code before and after and taking the higher score.

All in all, I was able to get some very plausible matches with high scores,

but there were always some false matches mixed in. I would have been happier to

accept that it missed some matches than that it was matching together tings

that really weren’t the same, but it really wasn’t possible to define clean

cut-off point based on scores and confidence levels. Then I hit on the idea of

not using a score cut-off, but rather insisting that any matches must work both

ways. So, my reasoning was that if the highest-scoring match for firmware FA

table TA in firmware FB was TB, then if this was a genuine match it should work

the other way around and the highest-scoring match for firmware FB table TB in

firmware FA should be TA, whereas if it was spurious match then it would be

more likely to link back to say TC. On this basis I prepared some

correspondences between tables in pairs of firmwares, and then compared them to

the hand-generated correspondences before. It was all a bit disappointing.

There were a lot of differences, and when I looked at them, in lot of cases it

had found very high degrees of match in both directions between tables that

were just unrelated. It began to feel like some of the things we found when

testing ChatGPT AI at work; it always seemed to be able to give a very

plausible and convincing answer, even with very plausible and convincing

reasoning behind it, but it was probably wrong!

It was all beginning to feel a bit desperate, so I left it alone for a

few days to think.

One thing I realised was how much code I had seen that was very

similar across ECUs that were very different. For example, the Rover 75 / MG ZT

line of ECUs are in many ways a lot more distantly related to other MEMS3

applications that the other MEMS3 applications are to each other. They use a

lot of BMW-class security and have a lot of code differences. But the Rover 75

Turbo ECUs have a lot of additional turbo-related code over the Rover 75 NASP

ECUs, and large parts of this extra code were identical to code I’d seen in the

development MG ZR Turbo firmwares, where it was added in to the regular ZR ECU

instead. It seemed as though the “modular” in Modular Engine Management System

(MEMS) carried over into the software design as well as the hardware; it felt

like there was basically a master menu of different modules, and all of the

MEMS3 firmware variants were essentially made by selecting a subset of these

modules at compile time. It was almost as though you could draw up a “master

MEMS3” firmware containing everything, and then just delete the bits you didn’t

want in any given ECU. The different modules even seemed to appear in petty

much the same sequence in the code wherever they appeared together. So, I

decided to see if I could try to find the common modules, and use those to

identify tables.

This is how I went about it:

·

Convert each binary

firmware to a text listing by passing it through a disassembler.

·

Convert each

listing into a “comparable form”, line by line. This meant:

o

Stripping out

comments inserted by the disassembler.

o

Stripping out labels,

as the code modules would be compiled at different addresses in different ECUs.

o

Stripping

consecutive whitespace from the disassembled code, to ensure identical

instructions were always formatted identically (the whitespace could different

for example where corresponding addresses were 3 digits long e.g.

$FFE or 4 digits long e.g. $1002).

o

Stripping out

references to explicit scalar addresses, of the form “$NNN(a5”,

which I reduced to “$(a5”.

o

Stripping out

explicit 6-hex-digit addresses, to account for the fact that the code may be

compiled at different addresses.

o

Stripping out

addresses that looked like table addresses, so instructions of the form “move.w #$2NNN,d1” or “move.w #$3NNN,d1”.

o

Stripping out

variable addresses (valid RAM addresses of 1, 2, 3 or 4 hexadecimal digits in

several forms of instruction used to refer to RAM variables).

o

Stripping out bit

numbers for Boolean flags, as the compiler may pack different bits into bytes,

so treat them as addresses.

o

Stripping out

branch lengths. In 68000 assembly, branches to other addresses may be specified

with different size offset operands, and the compiler would use the shortest

instruction that would allow a long enough jump. If the modules were compiled

at different addresses it may be forced to use a long

branch, so all branch instruction lengths should be treated as equivalent.

o

Stripping out “null

subroutine” names. The disassembler distinguished between subroutines with

instructions, which it names in the form “sub_NNNNNN”, and subroutines which are

empty, which it names “nullsub_NNNNNN”. If a module was omitted, sometimes a

stub subroutine was called but nothing was compiled into it. From the point of

view of the calling code these two cases should be treated as identical, so I

converted “nullsub_” references into “sub_” references.

o

Stripping out

“data-defined labels”. The RTS (return from subroutine) instruction has the

hexadecimal code $4E75. Sometimes the disassembler would see this as being

string data, the characters “Nu”. Labels for subroutines that just contained a

return instruction that were pointed to in data would then be assigned in the

form “aNu”. In other cases, these would be assigned as “word_NNNNNN” where

$NNNNNN was the hexadecimal address. As this was just a quirk of the disassembler

and not a feature of the binary code, I converted “aNu” type references to

“word_NNNNNN” type references.

o

Stripping out all

constant binary data. Sometimes in the code there were blocks of bytes that the

disassembler had not managed to make sense of, and were just listed as byte

arrays. There were usually tables of records embedded inline in the code and

often contained addresses, meaning that they were different between firmwares,

so I replaced all constant byte blocks with a single DC marker.

Doing all of that meant that for each

firmware, I had a file which kept most of the “shape”, structure and detail of

the original code but in a form that was independent of the address at which it

had been compiled, and which was independent of other choices which the

compiler was free to make that were not explicitly features of the source code.

An example of some code converted to “comparable form” is shown below:

dc

bsr.w sub_

btst #,($).w

beq.s locret_

bsr.w sub_

rts

clr.w d1

move.b ($).w,d1

cmpi.w #2,d1

bcc.s locret_

movea.l off_(pc,d1.w*4),a0

nop

jmp (a0)

rts

dc

bsr.w sub_

bsr.w sub_

move.b #1,($).w

bra loc_

rts

bsr.w sub_

rts

rts

lea ($FFFFF230).w,a0

move.w #0,d0

move.w $(a5),d2

subq.w #1,d2

move.w #0,d1

bra loc_

addi.w #1,d1

cmp.w d2,d1

bgt.s loc_

move.w $(a5,d1.w*2),d3

move.w d0,d4

add.w d3,d4

move.w d4,(a0,d1.w*2)

bra loc_

move.w #0,d4

addi.w #$3F,d4

move.w d4,(a0,d1.w*2)

move.w #$3D,($FFFFF20A).w

move.w #$500,($FFFFF20C).w

bclr #,($FFFFF210).w

rts

move.w ($).w,d0

sub.w ($).w,d0

ext.l d0

divs.w #$64,d0

bpl.s loc_

addi.w #$48,d0

As you can see can see, the text still

retains a lot of the original details which means that it is good for matching

reliably, but has no information about the address at which it was compiled.

Stripping out all of the address information has certainly not left featureless

code that could match anything. Numeric constants (such as the $3F shown above)

which were not treated as addresses were retained, as were addresses outside of

the RAM and EEPROM address ranges (such as the $FFFFF20A register address shown

above). Register numbers were also retained.

The algorithm then proceeded as follows:

·

Look for the

longest runs of identical matching instructions (at any address, in comparable

form as above) in the two firmwares.

·

Cut out the

assembly source code for these blocks and add to two lists of matched

instructions (the instructions before and after these blocks remain in the

original source lists following each other).

·

Repeat until the

longest matching run is less than 32 instructions (below which the matching may

not be reliable).

·

Sort both lists

based on the original source addresses in the first list (to put any procedures

broken apart back together etc.).

This would then result in two lists of

instructions which were known to correspond exactly in the two firmwares. I

just hoped that large sections of the code could be matched up this way.

I tried running this between a VVC and a

non-VVC MPI K Series firmware and the results were really surprising, and a lot

better than I could have expected:

·

In the first pass

it found a single run of over 12,000 consecutive identical instructions.

·

Subsequent passes

continued to find runs of several thousand instructions.

·

When it finished,

it had matched up:

o

33,964 out of

35,859 instructions in the VVC file, leaving 1,895 unmatched, covering 94.7%

of the code.

o

33,964 out of

34,543 instructions in the MPI file, leaving 570 unmatched, covering 98.3%

of the code.

So what it was telling me was that the VVC ECU was basically identical

to the MPI ECU, plus about 1,300 code instructions that were specific to the

VVC. The MPI code that it had not matched to code in the VVC ECU really was

just made of scraps where there were minor differences between the two. It only

contained 18 scalar references and no table references at all, meaning that

every single table used in the MPI ECU also existed in the VVC ECU and could be

correlated exactly.

Now I had a method that could reliably

identify all of the corresponding code between any given pair of firmwares, it

was easy to scan the two lists and pull out the corresponding table and scalar

references in each. For example, where I had found a run of say 3000 identical

instructions in the two firmwares (after converting to the comparable form

described above), and instruction number 1523 in each of them referred to a

table, I could be pretty much 100% sure that the two tables in the two

firmwares were exactly equivalent.

In my library of files from vehicles and

from the T4 CDs, there are 40 petrol firmware versions and 13 diesel firmware

versions. This meant there were 40*39=1560 possible pairs of petrol firmwares

to compare and 13*12=156 possible pairs of diesel firmwares to compare. It was

not possible to cut this by a factor of 2 by assuming that the comparison

operation is symmetric and so comparing firmwares FA and FB also gives us all

of the information about a comparison of FB and FA. I had to consider the

possibility that in a later firmware they may have split a table into two,

meaning that if table TA was referred to in two places in firmware FA, the

corresponding code in firmware FB may refer to two different tables TB1 and

TB2. In this case, both TB1 and TB2 would be listed as correlating to TA as all

of the code referencing TB1 or TB2 would correlate to code referencing TA, but

TA would not correlate to either TB1 or TB2 as the correlation information was

inconsistent.

That made a total of 1726 pairs of

firmwares to compare; each of which needed every possible run length of

instructions at every possible combination of base addresses comparing, which

was a pretty enormous number-crunching job. I optimised the code as far as I

possibly could (lock-free thread-safe code that I could run in parallel, using

integer indices into a hash table of strings which meant I was comparing

integers instead of strings etc.) and ran it on 12 threads in parallel on a

6-core computer. It still ran the machine at 100% CPU usage fat out for a total

of more than 13 hours (but this didn’t matter as it was a one-off job). The

results were, for each possible pair of firmwares:

·

A CSV file listing

all of the correlated instruction addresses.

·

A CSV file listing

all of the correlated table addresses.

·

A CSV file listing

all of the corelated scalar addresses.

·

A CSV file listing

all of the correlated RAM variable addresses.

·

A text file listing

all of the instructions in the first firmware that did not correlate with

instructions in the second firmware.

I then added code at the end which

consolidated all of the above, grouping together e.g.

all tables which correlated to each other in different firmwares. I was quite

tight on my definition of a common “class” of tables. I listed all tables in

all firmwares. For each one that was not already assigned to a class, I looped

over the other firmwares looking what it correlated to. These correlated tables

were only added into a class with the table in question if they in tun

correlated back to every table already in the group in the corresponding

firmware. This meant that I grouped together tables in group of firmwares only

where they all correlated directly with every other table in the group to be

safe. This produced (in each case, one for petrol, one for diesel – click the

links to see the files produced):

·

A file listing the

correlated code addresses across all firmwares. Petrol

Diesel

·

A file listing the

correlated table addresses across all firmwares. Petrol

Diesel

·

A file listing the

correlated scalar addresses across all firmwares. Petrol

Diesel

·

A file listing the

correlated RAM variable addresses across all firmwares. Petrol

Diesel

Some brief notes on the above files:

·

Each file has a

header record with the firmware versions across the top.

·

Each file has a

“Class” column down the left, where the code has assigned consistent names to

each class based on which firmwares they appear in.

·

Each file has a

“Count” column which identifies how many firmwares each class was identified

in.

·

The tables files

have additional header records. The ECU places an index of pointers to the

table data locations at the end of the map. In the code, the tables are

referred to by their fixes addresses within the index (which is the address of

a pointer to the table data, not the actual address of the table data itself,

as this may vary from one map to another depending on the sizes of other

tables). When I first started developing MEMS Mapper I didn’t fully understand

this structure in the code and so I referred to the tables based on their

position in the index, table 0 being the first (and not usually a normal table

in petrol ECUs where it is only axis data, with the body data in RAM), then

table 1, tables 2 etc. In hindsight it would have been better and more

consistent to have identified the tables by their index pointer addresses, but

the definition I have used is still valid and workable. To convert an index

address to a table number, we need to know where the table index starts, i.e. the address of the pointer to table 0. In petrol ECUs

this is easy to find, as the special RAM table 0 has its own lookup function.

Find this, and the address it uses is the address of the index entry for table

0, with the rest following as consecutive two-byte offsets. In diesel ECUs,

every table is “normal” and every table appears to be referenced in code, so

instead I assume that the lowest address of any table accessed in the code is

table 0.

It's clear from those files that there’s

a huge degree of commonality across all of the MEMS3 firmwares. For example,

there appear from these files to be 250 unique tables used across the whole

petrol MEMS3 range (it’s actually slightly fewer in reality, see below). Of

those, 123 are shared across all 40 firmware versions and so appear in all

petrol firmwares. With any given firmware using about 150 tables, that’s about

80% of the tables common across the whole range. A further 27 tables appear in

30 or more firmwares. You can clearly see where blocks of tables, scalars and

firmwares appear in whole sets of related firmwares for VVC, turbo or automatic

ECUs. This clearly validates the original assumptions about the modular

structure of the various firmwares.

One interesting observation is that he

“Base” and “Turbo” modules clearly both contain a definition of the ignition

timing base map. So non-turbo ECUs all have one ignition timing base map, while

turbo ECUs end up with two copies. The copy corresponding to the “Base” module

still exists in turbo ECUs but isn’t referenced anywhere in the code as the one

from the “Turbo” module appears to override it. The “Base” version of the

ignition timing map then often contains a full but completely different and

inappropriate ignition timing map, inherited from the “Base” module (the

structures of the two tables are absolutely identical, it’s just the numbers

that differ). As an aside, this sort of thing is seen in other places in the

ECU too. When you’re working on the code, you soon realise that the base ECU design

supports up to 8 cylinder engines. The number of

cylinders is set at compile time, so you see a lot of loops from 1 to 4 looping

over the different cylinders, but the data structures behind them are 8 entries

long. Rover only ever used the MEMS3 in production on 4

cylinder engines, but they clearly experimented with it with the KV6

engine. For example, there is an array in scalars that gives the engine angles

at which each cylinder reaches TDC. This is 8 entries long, the first 4 values

are always correct for a 4 cylinder engine, but

entries 5 and 6 (not referenced in code that only loops over the first 4

entries) contain the values which would be correct on a KV6 engine. The last

two entries are unused and contain 0; Rover never did put a KV8 into production.

To validate the approach further, I then

compared the petrol tables file with the one I had made by hand previously.

This was the point at which previous algorithms had been found wanting. In this

case, the agreement was very good indeed, with a few exceptions:

·

There were a few

cases where the code handling a table had changed significantly, but by eye I

could see that the overall definition of the table was the same. In these cases the automated algorithm had not necessarily put them

together as one class where I had in my file.

·

There were a few

cases where I’d clearly got it wrong when doing it by hand.

·

There are a few

tables in some firmwares which just seem to be redundant and are never

referenced in code. By hand, I’d matched some of these up based on the data

they contained. The automated algorithm had nothing to go on as there were no

code references, so had left them unmatched. To be fair, if they’re not

referenced in the code they’re not really “the same” or “different” when

classifying them based on the code that uses them so I could happily accept

this as being correct.

I only found one single instance where

the automated algorithm had paired tables together where I believed them to be

different, and that proved to be very interesting. Both the final

code-alignment algorithm and the latest version of my proximity-scoring

algorithm both insisted that these two tables were equivalent:

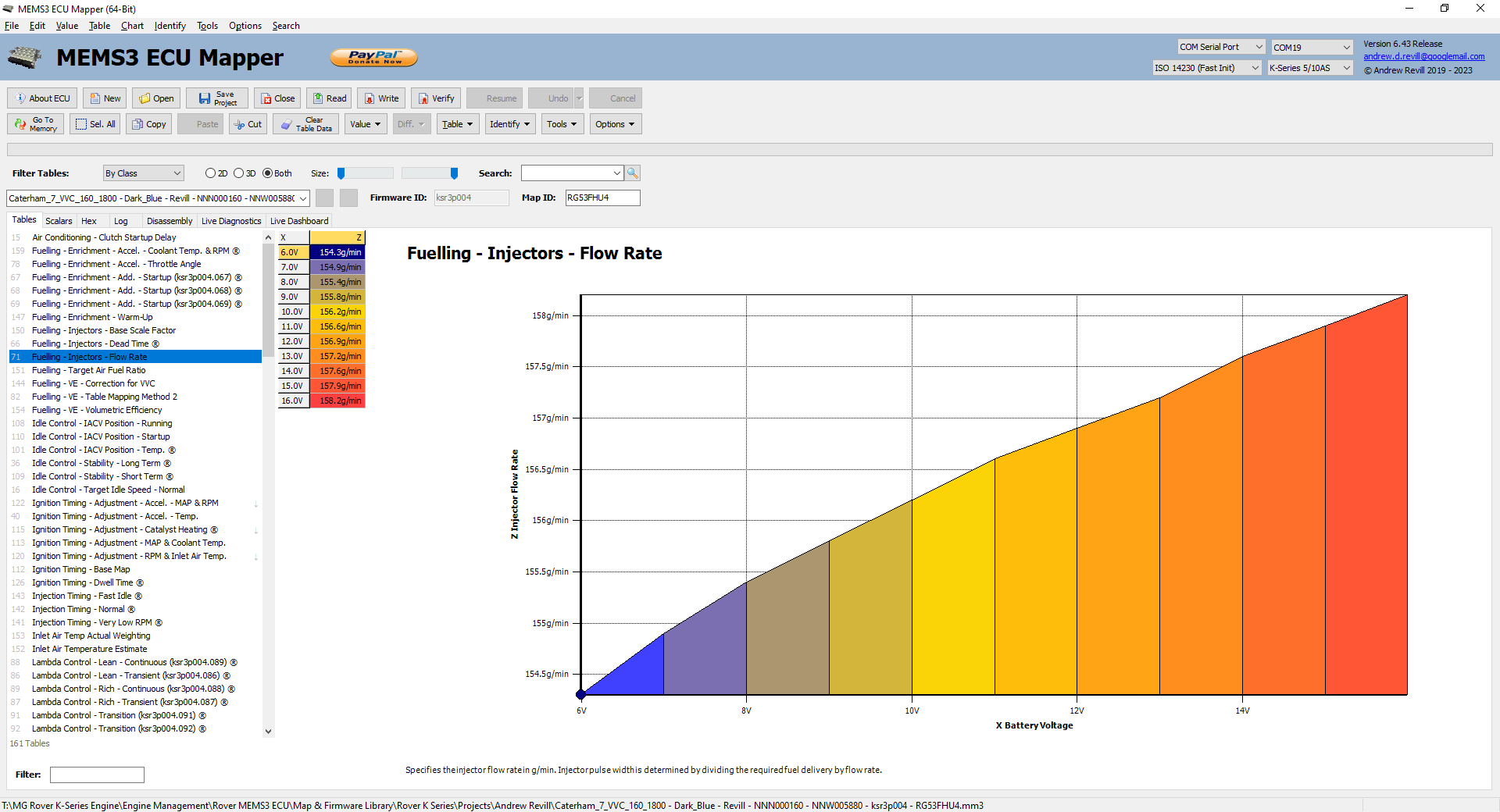

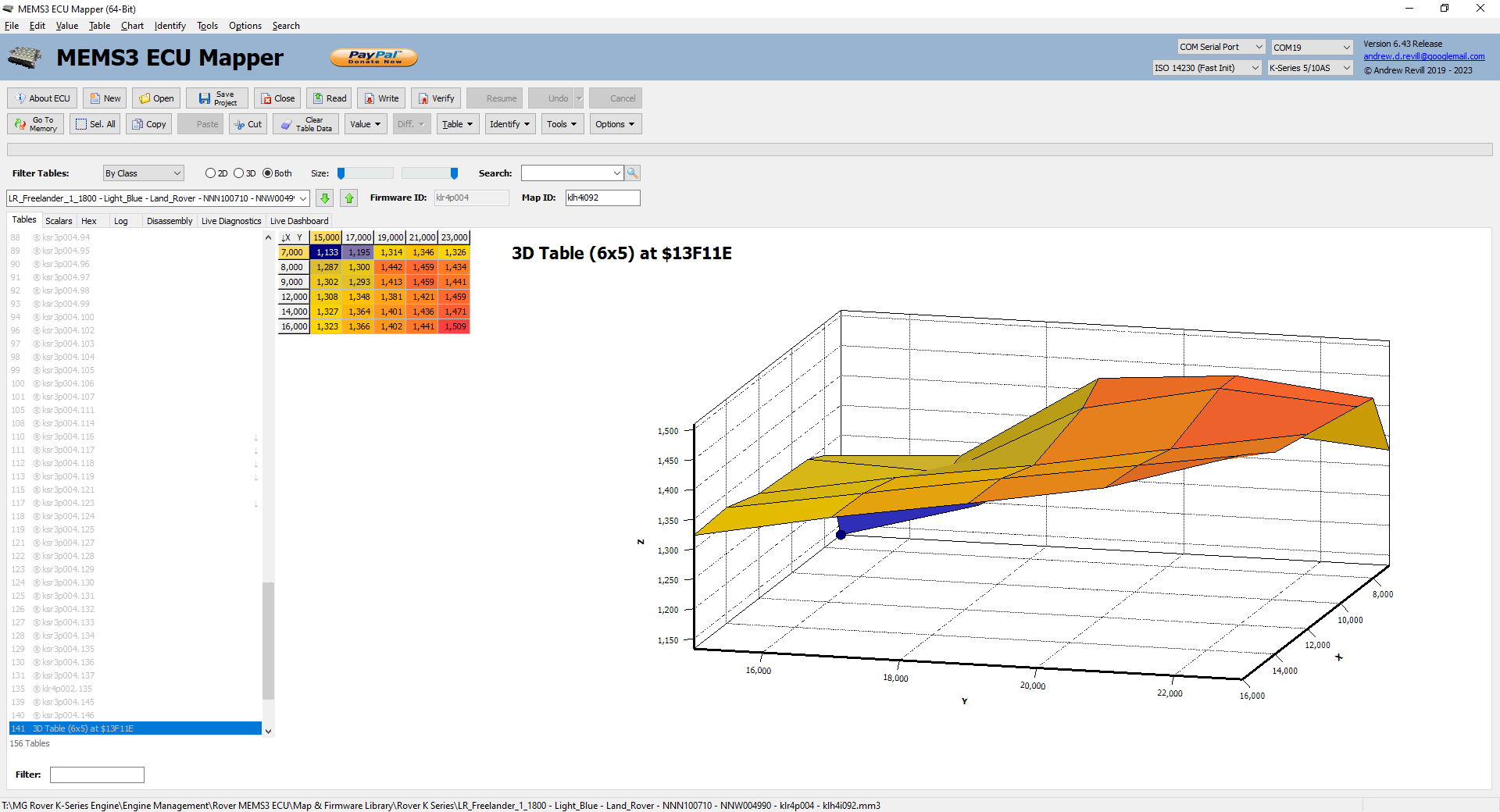

Initially that seemed to make no sense at

all, as one was a 2D table and one was a 3D table. The 2D table appears in

nearly all of the petrol MEMS3 firmwares and gives the injector flow rate as a

function of battery voltage (note this is not related to the “dead time” caused

by the difference in opening and closing delays on the injector as this is

modelled separately, but models the actual flow rate during the time the

injector is open; it appears to make a small allowance for the fact that at

higher battery voltages the pump will work harder pushing more fuel through the

regulator, and there is inevitably some degree of “softness” or natural

impedance to the regulator, therefore the fuel pressure will rise slightly with

increasing battery voltage). The 2D table does not appear in Land Rover

Freelander ECUs. The 3D table only appears in Land Rover Freelander ECUs. This

would only make sense if the second axis was fuel pressure, but this would

require the Freelander engine to have a fuel pressure sensor which is not

present on any other K Series engine I’ve seen. A bit of Googling turned up

this: https://www.autodoc.co.uk/car-parts/sensor-fuel-pressure-12909/land-rover/freelander/freelander-ln/15591-1-8-16v-4x4

- a Freelander 1.8K Fuel Pressure Sensor! So the

automated algorithms was right and I was wrong. This was indeed the equivalent

table in a Freelander ECU, which I would never have spotted just looking at the

data. Looking at the code, there’s just one extra line around the injector flow

rate lookup where the ECU loads the fuel pressure variable into register d3.

The proximity-scoring algorithm had recognised the identical code either side

and scored it highly enough to count as a clear match. The code-alignment

algorithm had extracted the runs of identical code before and after, then in

the final sorting stage had put them back together again, leaving identical

code listings with the one single additional instruction ending up on the

“uncorrelated” list.

To take into account the few places where

I had put things together by eye where the automated algorithm had missed them,

I manually realigned the two petrol table files to produce this: Tables.RoverKSeries.Override.xlsx.

The final piece of the jigsaw was to add

code which would automatically update the definition files used by MEMS Mapper

with all of table and scalar information generated above. This is now done and

included in the in the latest builds available for download.

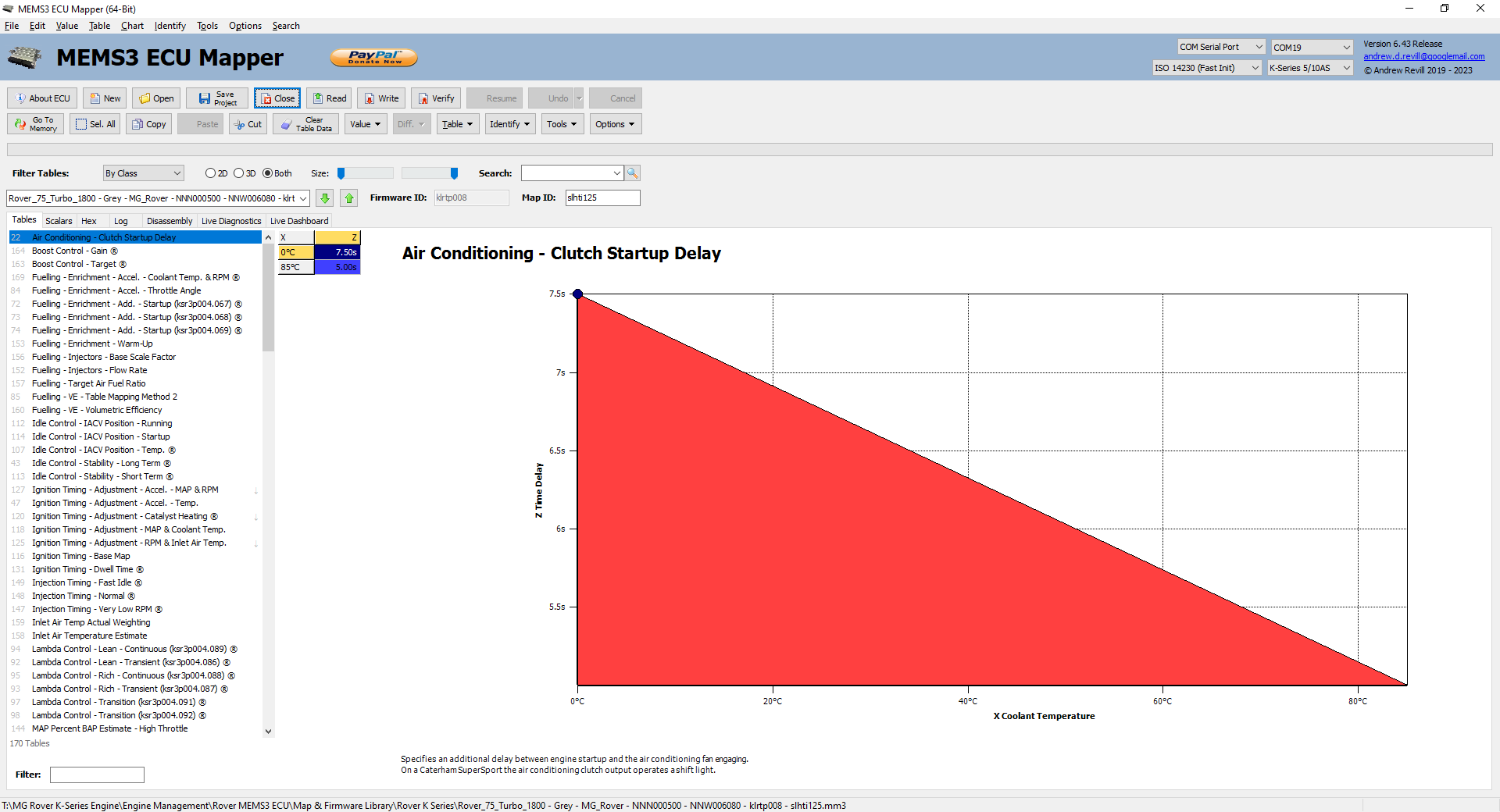

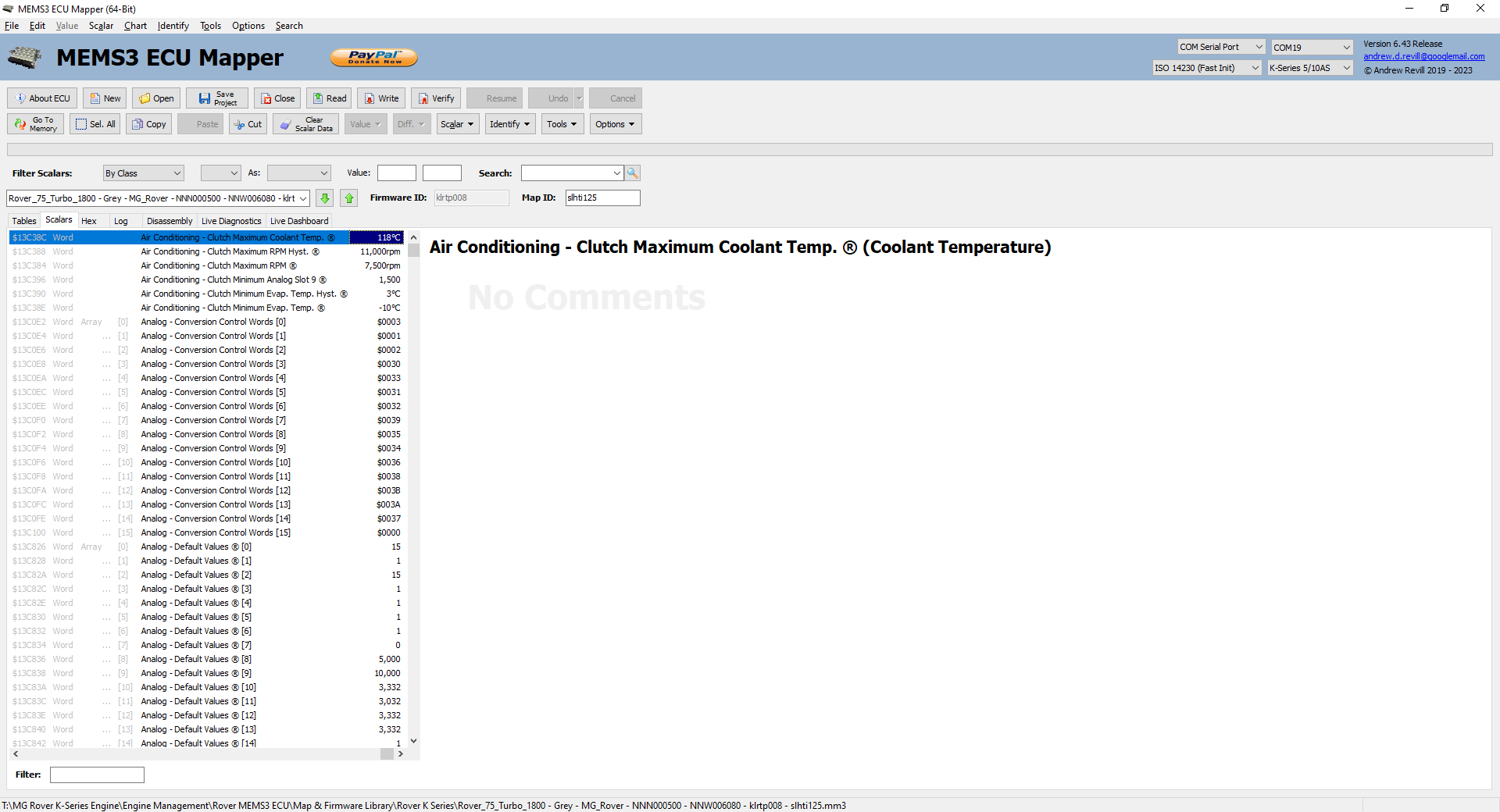

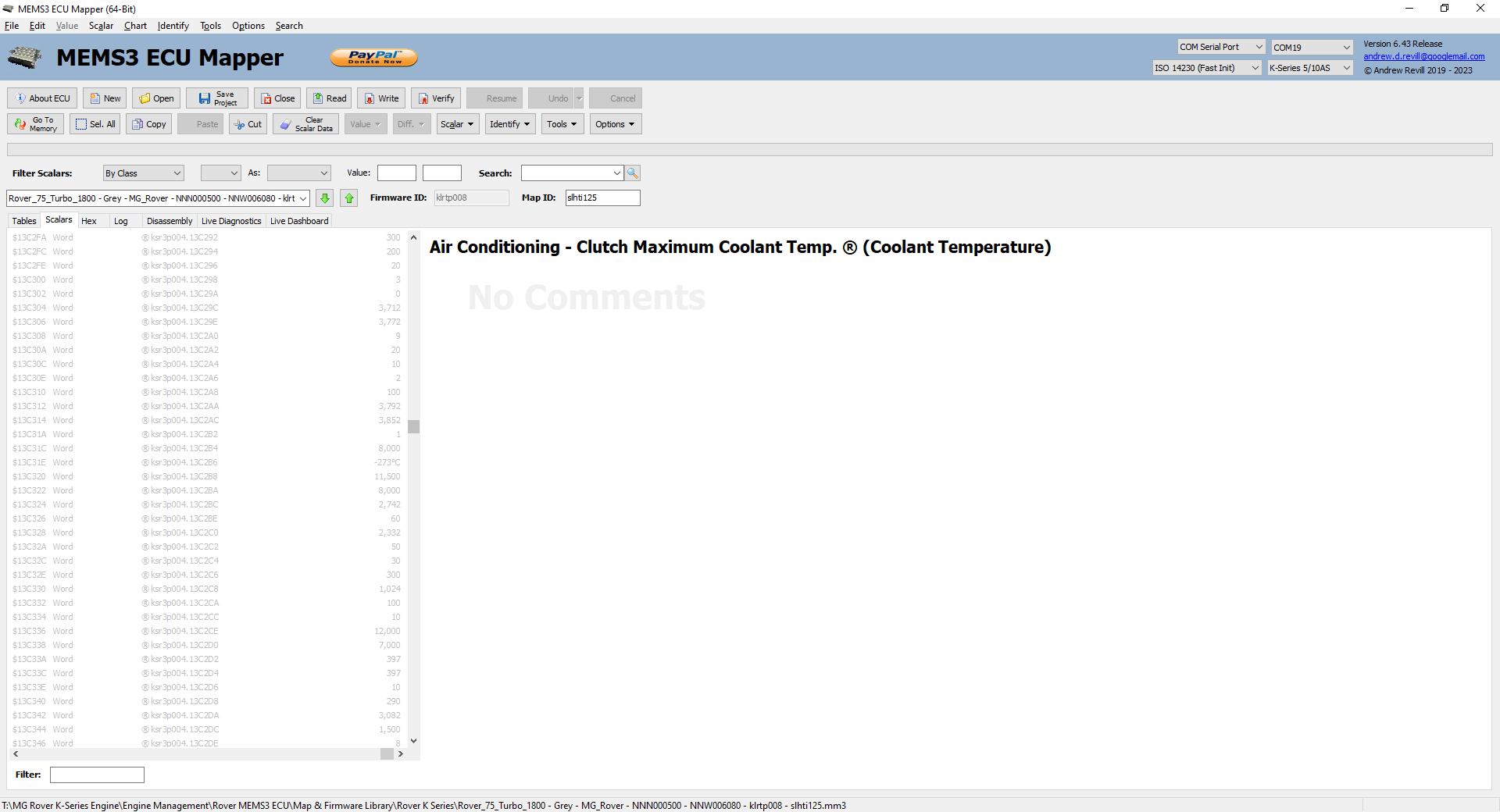

And The Result Is …

Every table and every scalar I’ve ever been able to identify in any firmware version (mostly in the

ksr3p004 VVC firmware as that’s what I’ve focused on during research) now

appears correctly defined in files for all other firmware version which use it

(in this case a Rover 75 ECU). And because I’ve classified all of the matching

tables and scalars, even where I don’t know what they do yet, any tables and

scalars that I identify in any firmware version in the future will also appear

in files for all other firmwares which use them. Every single table and nearly

every single scalar in every firmware is now assigned to a class definition.

The only exceptions are those that are only used in one single firmware

version, and the few scalars which are not directly references in code (there

are mostly references as pointers in tables of data records, and are not

therefore susceptible to this technique). In theory, this should mean that the

in-application data-based matching algorithm should not need to be used in

future.

It’s a big step forward in terms of

consistently analysing and classifying the data definition used by all of the

different MEMS3 firmware versions.

Now back to the engine simulator and

disassembler to try to identify more features. Oh yeah … I haven’t written up

my full engine simulator yet, have I? There’s another project to document when

I can find the time!